Application of high temperature 3D printer in space maintenance

Antinsky 2021-12-12

Antinsky: in the past 70 years, the number of satellites in earth orbit has increased sharply. It is said that there are now more than 2500 satellites across our planet's atmosphere. Once these equipment in extraterrestrial space fails, their maintenance will undoubtedly be a costly project.

On December 10, 2021, the Antarctic bear learned that engineers from the University of science and technology of China and the University of Sydney jointly designed a 3D printer, which can process peek materials at high temperature under simulated space conditions.

According to the team, using FDM 3D printing, it is possible to produce peek satellite spare parts in orbit, but the insufficient heat conduction in space will cause the current system to overheat. In order to overcome this problem, researchers have developed a new 3D printer with proportional integral (PI) controller, which can operate at a high temperature of up to 400 ° C in vacuum, which may make it an ideal choice for future track maintenance tasks.

Satellite service challenges?

In addition to guiding space missions, the normal operation of satellites is also very important for communication and navigation on earth. Therefore, in case of failure, satellites may deviate from orbit, produce debris and damage the orbiter.

In theory, the on orbit manufacturing of satellites will greatly reduce the occurrence of satellite failures, and this method is cheaper than launching rockets filled with maintenance equipment into orbit. It is reported that Northrop Grumman, DARPA and other companies are now carrying out satellite launch missions. In these missions, their respective "extended aircraft" and "robotic aircraft" will also carry out orbit tests.

However, researchers from China and Australia say that the cost of on orbit manufacturing is expected to soar to $6.2 billion by 2030. In order to help aerospace companies reduce their expenses in this regard, the research team attaches special importance to the success of the 3D printing experiment on the international space station and suggests that the technology can be deployed in outer space and manned spacecraft.

In particular, engineers believe that FDM machines may be ideal for track maintenance because they have no laser, rely on easily stored filaments, and are compatible with strong materials such as PEEK. However, although they are optimistic about the technology, the team acknowledges that the current system is prone to material blockage in space due to excessive melting of filaments.

Printing in a vacuum in space

In order to make orbital 3D printing more feasible, the researchers began to develop a 3D printing system with an upgraded thermal control device, which can land on the satellite and then use the manipulator to replace the damaged parts. In addition to these arms and its landing gear, the team's first prototype is largely based on a standard FDM architecture with heating modules, sinks, roll belts, extruders and radiators.

In order to assess the potential of the machine before it was built, the team chose to do some simulation of PEEK printing. Interestingly, the results show that increasing the number of tropics between the heat sink and radiator of the equipment can more effectively control the temperature of the core tube and prevent the back flow of molten filaments during material feeding.

Through the simulation, the engineers also found that printing under the condition of reducing gravity will cause the material to adhere to the inner pipe of the system, increase the friction, and may cause extrusion and blockage. In order to solve this problem, the team repeatedly modified this part, and then proposed a design to improve its heat conduction efficiency and play a role at temperatures up to 400 ℃.

Finally, after sorting out all the data, the researchers designed a mathematical model to prove the benefits of introducing "fuzzy PI control module" to their system. In essence, the equipment is designed to start at 380 ° C, which improves the accuracy of its thermal control function, but also prevents the risk of overheating and maintenance errors.Great application potential of am in space orbit

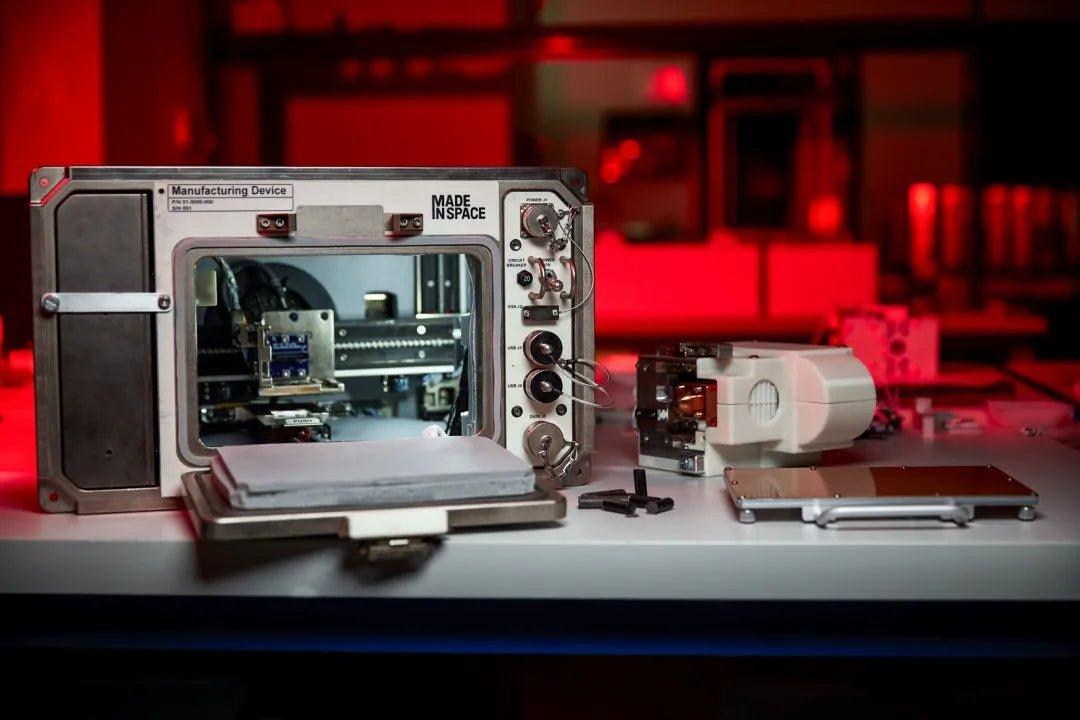

Space 3D printing may sound like science fiction, but the technology has been tested in extraterrestrial space on NASA's international space station. At present, one of the leaders in this field is made inspace, which now belongs to a subsidiary of Redwire. Last year, they installed a new ceramic 3D printing module on the track base.

In addition, the technology of made in space will also be applied to the commercial "orbital reef" space station to be launched by blue origin and Sierra space. The new base is expected to be launched in 2026 as a mixed use commercial park. At the same time, it will continue to provide a test site for microgravity R & D and experimental production for "space manufacturing".

At the same time, at the University of Applied Sciences in Munich, researchers adopted a method similar to that of the China Australia team and developed an orbiting satellite 3D printer. The system aims to reduce the amount of fuel required to launch maintenance equipment into space and limit the length of the mission. In the future, the whole solar panel or antenna related components can be built under zero gravity conditions.