1、 Problem Description

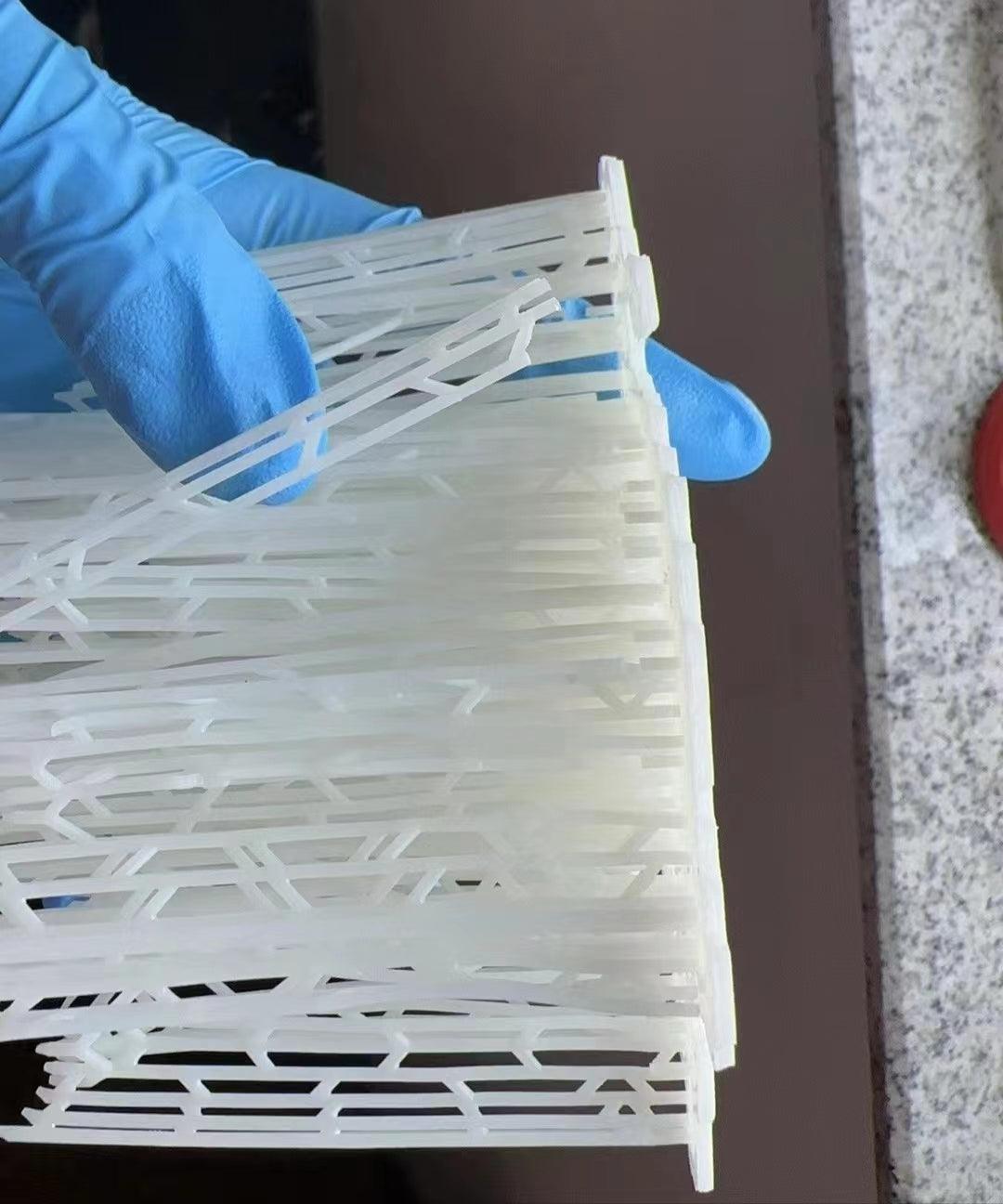

The model was printed normally without any issues, but the connection between the support and the bottom valve was broken or detached.

2、 Solution ideas

1. Consider whether the transition layer is sufficient for the connection between the bottom plate and the support

2. A small number of individual reasons are due to the model being too heavy/lifting too fast, and the support being too soft due to low normal layer exposure. However, if the density is sufficient, the model will not detach from the support but will pull the support away from the bottom plate.

3、 Solution

Firstly, increase the number of transition layers, and if resolved, there is no need for the next step

2. Increase the connection diameter between the support and the bottom valve

3. Increase normal layer exposure and reduce lifting speed