説明

The price indicated on the webpage is not full. If you are interested, please feel free to inquire.

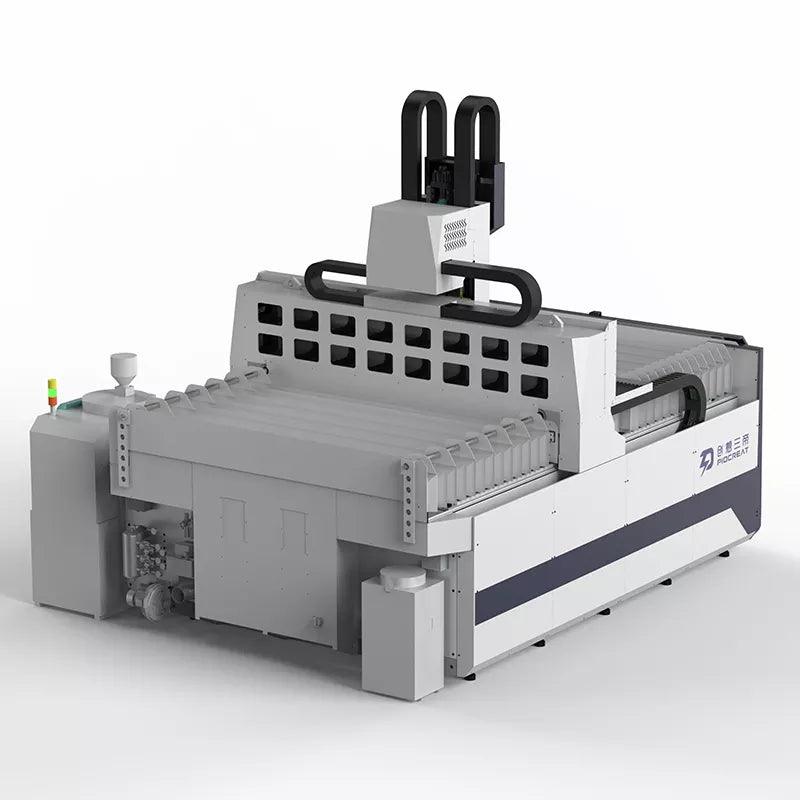

Creality PioCreat G40

The deposit is 5000USD Please communicate the final price with customer service.

Shenzhen Piocreat 3D Technology Co, Ltd was established in2015 and is an early manufacturer of 3D printer equipment. Basedon our independent R&D and self-innovation, we completely ownindependent intellectual property rights on our products. We focuson the R&D, production and sales of 3D printers for advertising sign,jewellery and dentistry, and large-size additive manufacturing. Relying on years of professional 3D prnting R&D and manufacturngtechnology precipitation, through continuous innovation, we provideexcellent 3D printers and solutions services for customers in adver-tising, jewelry, medical and dental, automobile, hand-made model and other industries

We have a large-scale production base covering an area of 10,000square meters, complete R&D, manufactuning and after-salesservices, and strong technical strength. We have advancedlarge-scale R&D centers, 3D printing laboratones, new matenalsresearch institutes and modern production lines in China, with24-hour uninterrupted professional testing lines and strict qualitycontrol systems to ensure product quality from the source

Quality depends on professionalism, and brand depends onservice. "We will rely on professional development, based in Chinafacing the world, and becoming a world-renowned enterprise in theapplication of 3D printing industry

|

3D printing parameters

|

|

|

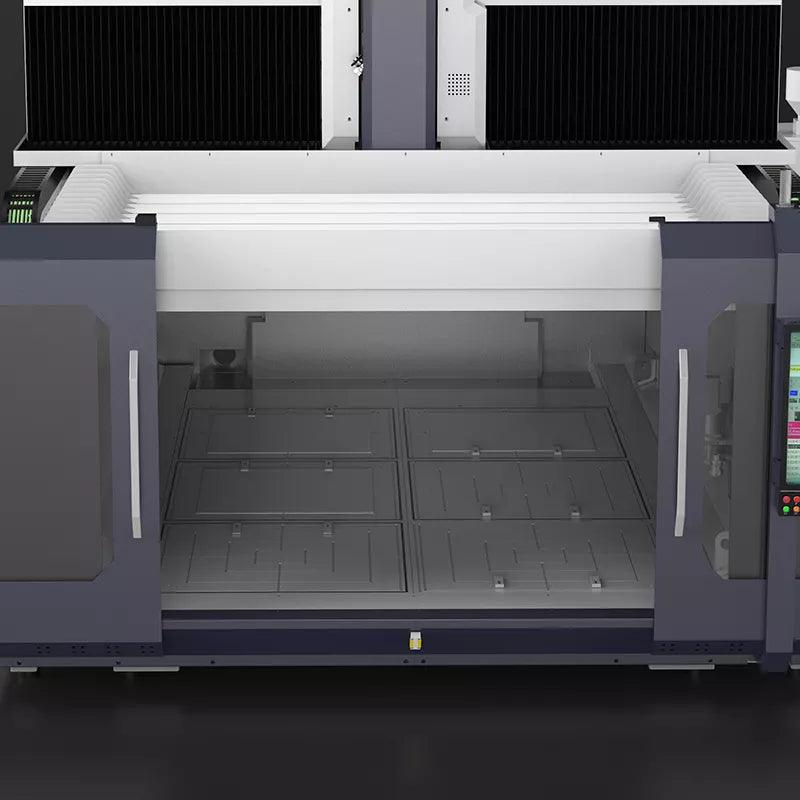

Printing Size

|

3725×2500×1330mm

|

|

Particles Diameter

|

2-5mm

|

|

Hybrid additive manufacturing and milling system

|

Yes

|

|

Machine Size

|

5962×4220×4800mm

|

|

Maximum extrusion volume

|

25kg/h

|

|

precision and repeatability

|

0.018/1000mm

|

|

Molding Tech

|

FGF

|

|

Bed Temp

|

≤200℃

|

|

Filament

|

PLA, PETG, ABS, PC, PA and other composite materials

|

|

Discharge structure

|

Screw extrusion

|

|

Nozzle Diameter

|

3-8mm

|

|

Nozzle Temp

|

≤450C

|

|

Power Voltage

|

AC380V

|

|

Slicer Software

|

Creality Print

|

|

Rated Power

|

65KW

|

|

Weight

|

15000KG

|

|

CNC machining parameters

|

|

|

Processing Size

|

3400×2500×1330mm

|

|

Processing Speed

|

20m/min

|

|

Spindle Power

|

8.5KW

|

|

Processing Mode

|

Five axis

|

High flow screw extrusion design

Equipped with 3-8mmlarge flow screw extrusion nozzleTo ensuring the stability and accuracy ofthe gantry ( + 0 . 02mm / 1000mm ) ,the printing speed is 10m / min and the processing speed is 15m / min

High-speed and high-precision five-axis head

quipped with 8 . 5KW / 24000 high-speed hvctUsing precision five-axis head , A axis 120'C , C axis + 320Cmachinable with plastic , carbon fiber and non-ferrous metals

High performance pressure wheel

Effectively improve the printing materials densitySelf-developed and researched high-performance pressure wheelaccording to the control printing pathcan effectively improve the density of the printing materialand make stronger the bonding between the printing layers

Wide range of printing materials

Can meet the application needs of different fieldsIt is suitable for printing all kinds of thermoplastic particles ,special mixtures materials , and ceramics and metal materialsSupports a variety of fiber composite thermoplastic polymer materials

Full-automatic provide dry materia

Automatic feeding dryingdehumidification three in oneThe full-automatic three in one feeding system providesconstantly dry materials , which can meet thecontinuous printing needs of 7 x 24 hours

OSAL Control System

32-inch full touch all-in-one machineAdopt OSAL control system and motion servo system ,32-inch full touch all-in-one machineto ensure equipment stability and machine response speed

Application field

Applied in various fieldsSuitable for producing large to very large thermoplastic materialsparts , molds , models and industrial tools , etcWidely used in aerospace , automobile manufacturing ,wind power , yacht and ship , home life , urban landscapeand other composite materials field