説明

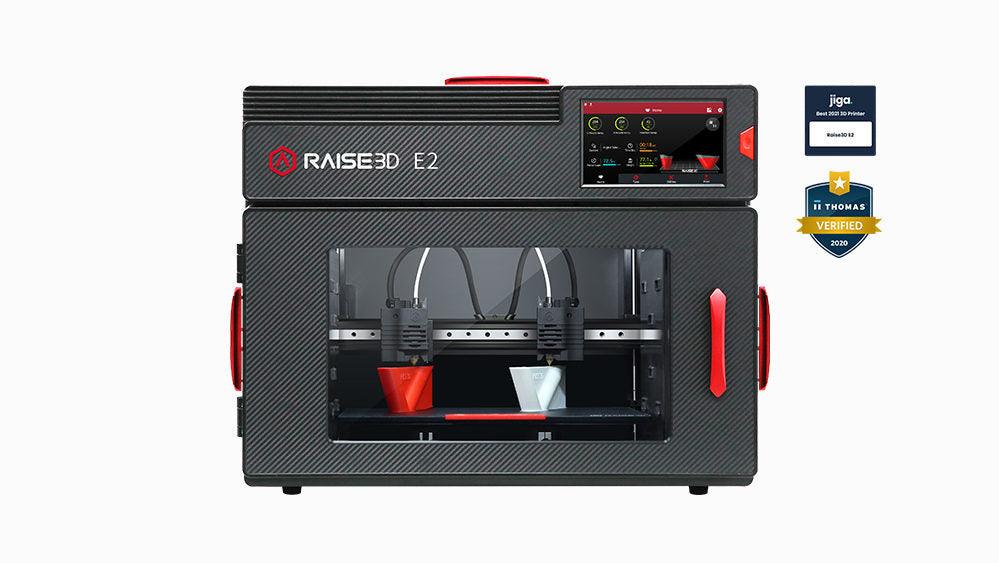

Raise3D E2 3D printer

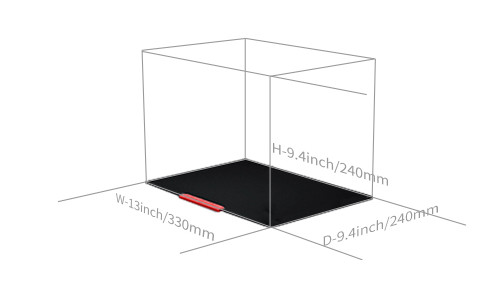

Raise3D E2 3D printer is a device working in FFF (Fused Filament Fabrication) technology, which involves printing fiber ductile thermoplastic material. The printer's working area depends on the number of extruders used. For a single extruder the working area is 330 × 240 × 240 mm, while for a double extruder 295 × 240 × 240 mm.

Raise3D E2 3D printer

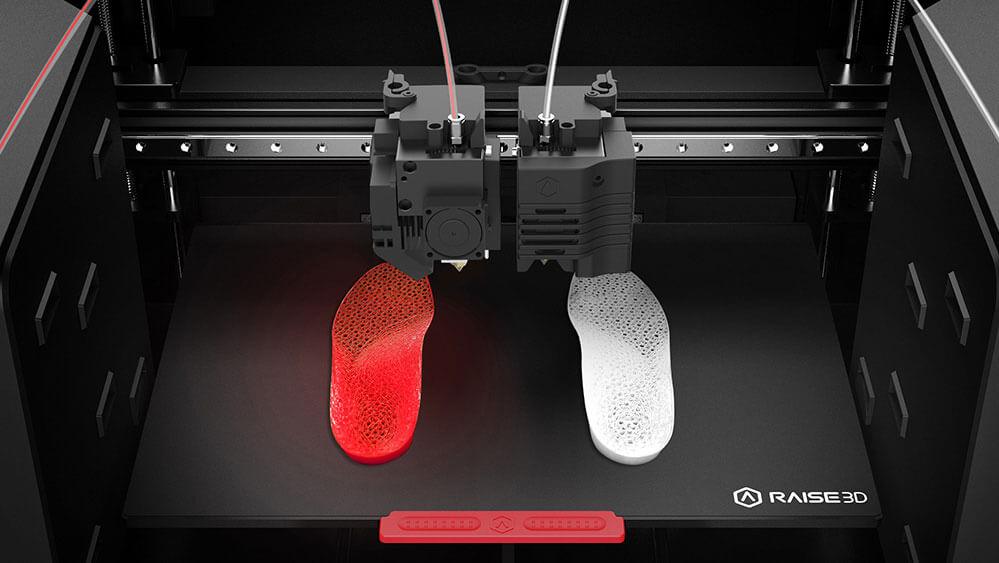

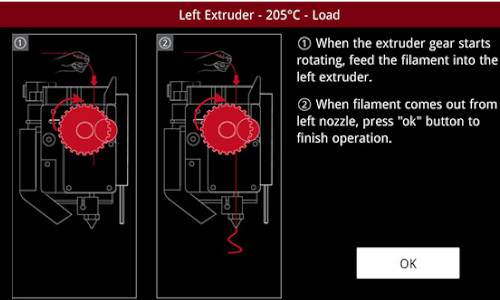

Raise3D E2 has two independent extruders, which increases printing efficiency. It allows you to print objects symmetrically reflected from each other or to print two of the same objects simultaneously. The speed of the heads is 30 - 150 mm / s. During printing, the nozzle temperature is a maximum of 300 ° C.

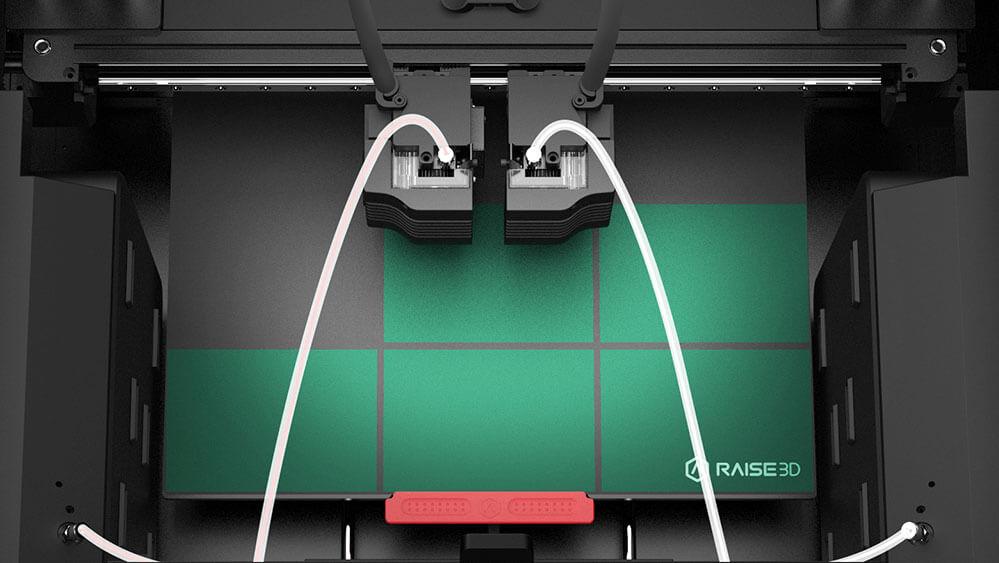

IDEX (Independent Dual Extruders) - Double prints

Raise3D E2 3D printer uses the Independent Dual Extruders (IDEX) technique. This is a 3D printing technique that allows two printheads to move independently. Each head has its own nozzle, which means that it can print from the same or different material than the other head. It has two modes: mirror mode and duplication mode. The mirror mode allows you to print symmetrical objects simultaneously, which increases productivity and shortens the printing time, while the duplication mode allows you to print the same objects simultaneously from two extruders, doubling the production capacity.

Raise3D E2 3D printer - Construction

The Raise3D E2 printer is a device with two independent extruders and a large working area. This allows freedom to print multi-material 3D objects, making printed objects precise and high quality. Raise3D Pro E2 has a built-in 7 inch touch screen and 2 USB 2.0 ports and 1 Ethernet port. The printer has a built-in 8 GB Flash memory.

Large working field

- For a single extruder the working area is 330 × 240 × 240 mm, while for a double extruder 295 × 240 × 240 mm.

- More options available for design.

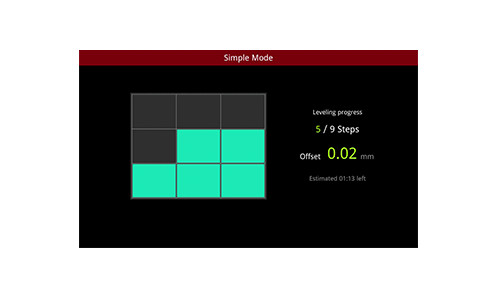

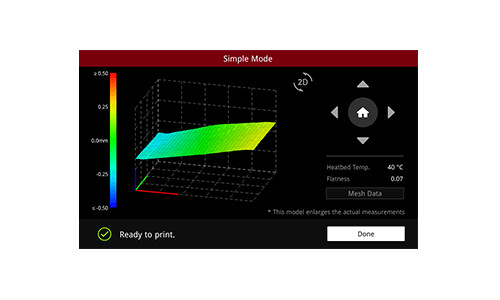

Automatic leveling

The printing platform is level during preparation for printing. ABL maintains the right distance between the print nozzles and the printing platform by creating a uniform print area. It improves adhesion and print quality, enabling the extruder to be adapted to even small changes in surface contour.

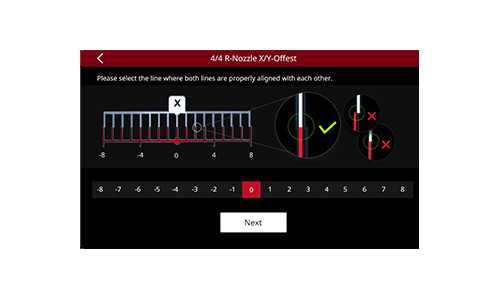

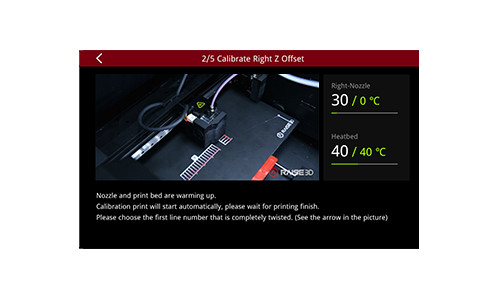

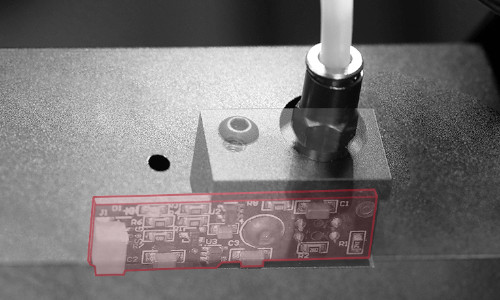

Video assisted offset calibration system

The system guides users through a simple video-assisted process to check if the Raise3D E2 printer is geometrically aligned. After completing all the calibration of the printer, the device can be used without any problems with properly set extruders.

Safety features and energy saving button

The Raise3D E2 printer has features that cause the door opening to be detected automatically, which immediately suspends printing, thus ensuring the safety of users. The device allows you to turn off RaiseTouch and LED lights during printing to save energy.

IDEX printer with a flexible mounting plate

The flexible mounting plate allows for easier removal of prints while minimizing potential damage to the printout.

HEPA filters

The Raise3D E2 printer uses HEPA industrial filters, which means that the device can be used in an office environment. The filter retains over 91% of particles that escape in other printers during printing.

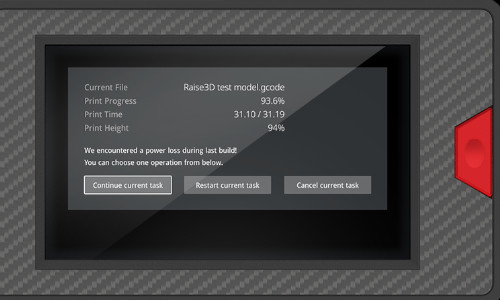

Resume printout

The Raise3D E2 printer allows for trouble-free printing even after a power loss. The device automatically saves the print progress before the power failure. The printing process resumes when power is restored.

Filament end sensor

The filament end sensor will automatically stop printing if the filament runs out. When the filament runs out, the red light blinks on the machine and printing stops. After the user completes the material, the printer resumes operation. The sensor will detect all types of filaments regardless of color, material and hardness.

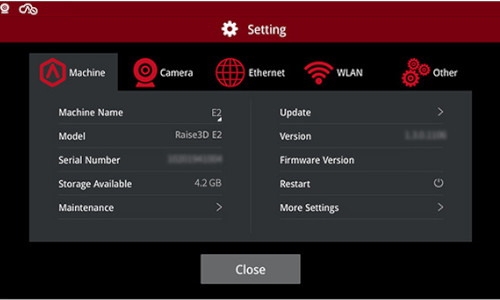

Intuitive service

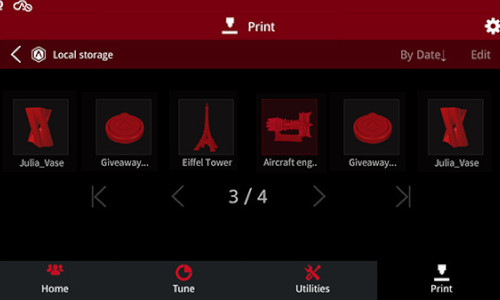

Visual interface / Quick overview / Visual printing progress / Full adjustment control.

The Raise3D E2 printer has a convenient, built-in high-resolution touch screen that allows you to view printing progress and allows full control of settings. Files for the printer can be read via USB and sent over WiFi. The built-in camera allows you to monitor the progress of work, the software provides the ability to remotely control the printer.

7 inch touch screen

Integrated setting control

Instructions

Visual model selection

The possibility of using many materials

Raise3D printers have been designed to ensure high material compatibility. To achieve the best performance and quality, select the appropriate print settings. For this purpose, the Raise3D Open Filament Program (OFP) was created. Filaments approved by Raise3D, which have been tested before, are sent to OFP. Print settings for such materials are included in IdeaMaker software to give users easier selection of the highest performance filaments.

PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Infused / Carbon Fiber Infused / Metal Fill / Wood Fill