説明

Yueming CMH1610

Key point of the Update on CMH series

1.CMH common model shares the same framewith K model(with up&down table)

2.Machine with small camera keeps the sameheight as common model

3. All models adopt transmission system withinner rail; Update on the general spare partsincreasing its universality greatly

All CMH models can be overstowed in 40HQ container without

uninstalling the machine feet to save both freight and labor cost

The collect box is dismountable in order to install the lifting system

2. Redesign the collecting box to improve the exhaust system

3. Machine with various configurations(universal version, CCD camerasingle or double heads) share the same upper cover.

Optional function: Lifting platform

The lifting part can be installed into the standard machine directly, just removing the collecting box.

Optional function: Top Camera

With the top camera install into the machine thecover will be removed

Full cover with top cover is optional

Optional function: Projector

With this function the operator is able to align the materialto the exact cutting area to ensure the cutting accuracyThe cover has to be removed while install the projector.

1 Adjust the height to save the freight(double deck in 40HQ)

The height of all Cmh machine is not higher than1100mmor exampleThe CMA1309-B-A, we need to remove its feet to put12 sets into a 40HQ but not for CMAH1390-B-Athe same 12 sets machine without removing thefeet

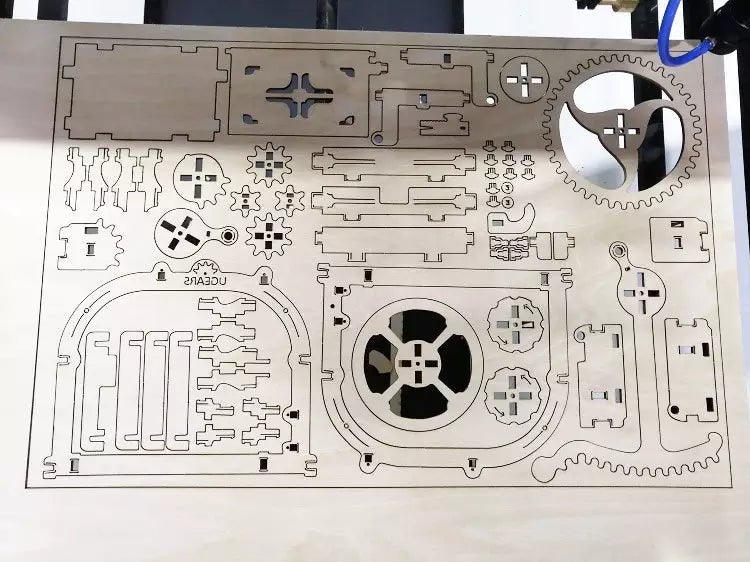

CCD camera on transmission system

New camera with internet access, reducing the bending of camera wire, lengthen its lifetime

Cutting head

External diameter of the lens holder is 25mm, with better concentricityThe lens holder is compatible with all 508mm, 63.5mm and 75mm lens. Choose different extension tube when cuttingdifferent material

Lifting platform

Lifting system consists of 4 threaded rods+ motor+belt, ensuring the stability of the lifting platformThe whole lifting system is an independent module, which can be added to the standard structure of CMHseries machine directly.

Machine cabinet

1. The cabinet of CMH is compatible with both standard working table and the lifting working table

2. The collecting box is formed in one piece sheet to enhance the exhausting performance. So does the sides of machine cabinet,to make sure its intensity and the stability of the transmission system during work.

3. The CMH adds an independent LED switch on the right side of the cabinet.

Cover

The side cover is now sealed by removable plate incase the customer wants to change higher powerlaser tube

Optimization on details

To shorten the installation time and decrease the percentage of damage, the fan will be formed on the metal part instead ofthe metal mesh And the size of the fan is enlarged from 80*80mm to 120*120mm to improve the cooling effect