Description

The price is a deposit, not the full price. You can contact us via email or WhatsApp before purchasing.

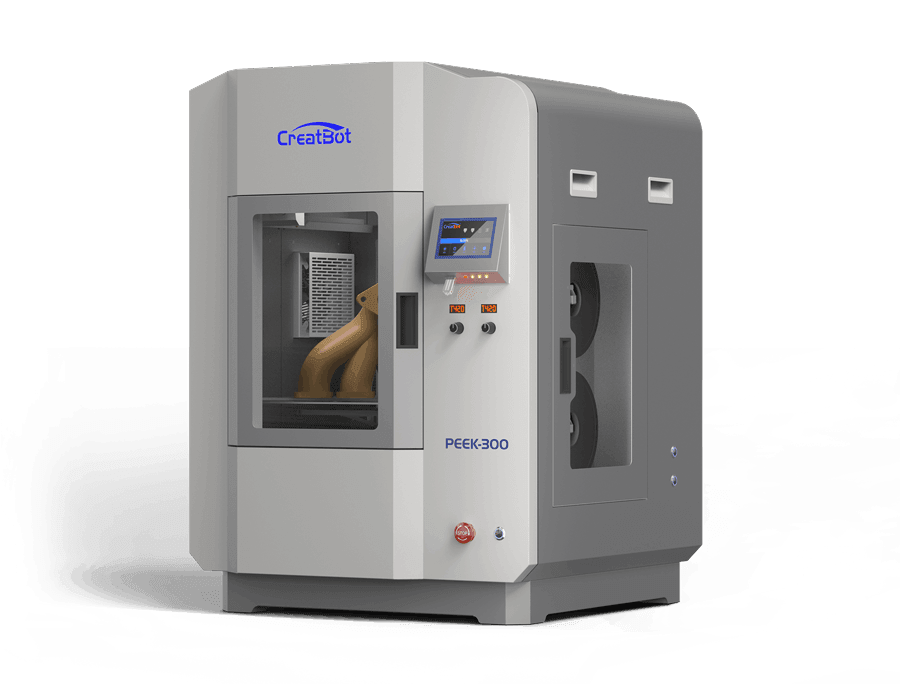

Creatbot PEEK-300

THE LEADER OF ULTRA HIGH PERFORMANCE 3D PRINTER

- Ultra high temp. nozzle/bed

- Advanced Thermal System

- Direct Annealing System

- Water cooling/ Heat isolation system

- Medical/Industry application

Direct Annealing System

Direct Annealing System (DAS), the world's first and extraordinary technology by CreatBot.Annealing process is instant controllable during printing. It aims to provide best quality parts in one time without warping and cracking printing of big size functional materials. (The technology is patent protected and available by CreatBot only)

DAS annealing process features :

1)Instantaneously:Finished during printing process, no need secondary treatment in oven.

2)Completely:The annealing process point to every extruded filament, not the whole printed model. The internal structure of the whole model could not be fully crystallized or will deform in oven.

3)Controllable:The surrounding temperature can be adjusted to 0-200 °C. the different requirements of toughness and strength can be met by adjusting the DAS temperature function at different material parts.

Smart Auto-rising dual extruders 480 ℃

The PEEK-300 equiped with CreatBot new technology smart Auto-rising dual extruders. Water cooling, DAS system, Auto-rising extruders. The dual nozzle temperature up to 480°C. You can print any 3D printer materials in the world. We can say it is best choice of polymer materials.

Hotbed 200 ℃

Common but necessary.

Base of printing big models with no warping.

Hot Chamber 120°C

Outstanding and important.

The protector of no cracking printing.

Cooling System

Cooling system is one of the important parts to constitute the whole thermal system. It is made of

(1) liquid cooling. Circulating liquid can be used effectively for a long time.

(2) Air pump cooling. Air pump provide cold air from outside instead of hot air inside chamber.

Product Parameter

| Printing | |

| Build Volume | Single Extrusion: 300*300*400 mm Dual Extrusion: 240*300*400 mm |

| Filament Diameter | 1.75mm |

| Number of Nozzles | Dual Extruder |

| Print Speed | 10-120mm/s |

| Nozzle Diameter | 0.4mm (0.3~1.0mm optional) |

| Filament Compatibility | Engineering Plastics: PLA, ABS, ASA, PC, Nylon, PETG, PVDF,TPU,Carbon Fiber; High temperature Material: UltraPA, UltraPA-GF, UltraPA-CF, PPSU, PEI(ULTEM); Ultra-performance material: PEEK,CF-PEEK (Carbon fiber), GF-PEEK (glass fiber), PEKK, etc. |

| Electrical | |

| Input Power | 200V~240V, 20A |

| Rated Power | 4600W |

| Screen | 4.3'' full color touch screen, multi-language |

| Print Method | USB Connectivity/USB Disk |

| Mechanical | |

| Cooling | Air pump cooling & water cooling |

| Platform | PCB aluminum + PEEK print board |

| Positioning Precision | X Y axis 0.0127mm, Z axis 0.00125mm |

| Extruder | Directly Drive |

| Machine Construction | Fully enclosed hot chamber |

| Bed Leveling | Manually/Automatic |

| Temperature | |

| Nozzle Max. Temperature | 480℃ |

| Chamber Temperature | 120℃ |

| Platform Max. Temperature | 200℃ |

| Direct Annealing Temperature | 0~400℃ |

| Software | |

| Software | Creatware, Simplify3D, Cura, Slic3r |

| Operating Systems | Windowsall, macOS |

| Print File Type | STL, OBJ, AMF, Gcode |

| Special Function | |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Direct Annealing System (DAS) | Annealing process is instant controllable during printing. It aims to provide best quality parts in one time without warping and cracking printing of big size functional materials. |

| Heat insulation | Triple heat insulation |

| Emergency stop switch | Support emergency stop |

| High temperature accessories | High temperature resistance motors, linear rails, belts and circuits to ensure long time high temperature printing. |

| Size & Weight | |

| Machine Size | 650*600*750 mm |

| N.W | 100 kg |

| Packing Size | 820*720*1080mm |

| G.W | 145 kg |