Scale prototyping and production as your business grows with the Kings-450Pro, an affordable, industrial SLA 3D printer that

consistently delivers.

SLA 3D printer, also known as stereo lithography 3D printer, or laser 3D printer. SLA is an abbreviation of "Stereo Lithography Apparatus", which is an abbreviated form of stereo lithography.

Technical principle

Focusing on the surface of the photocurable material with a laser of a specific wavelength and intensity, from point to line, from

line to surface solidification, complete a level of drawing operation, then move the lifting table vertically in the height of a

layer, and then solidify Another level. This layer stacking constitutes a three-dimensional entity. SLA is the first practical

rapid prototyping technology, using liquid photosensitive resin raw materials.

Technical principle

Focusing on the surface of the photocurable material with a laser of a specific wavelength and intensity, from point to line, from

line to surface solidification, complete a level of drawing operation, then move the lifting table vertically in the height of a

layer, and then solidify Another level. This layer stacking constitutes a three-dimensional entity. SLA is the first practical

rapid prototyping technology, using liquid photosensitive resin raw materials.

|

BASIC INFORMATION

|

|

|

Apparatus Size(without display):

|

104cm(W)*117cm(D)*192cm(H)

|

|

Rated Dissipation

|

1.2KVA

|

|

Apparatus Weight

|

about 800kg

|

|

LASER SYSTEM

|

|

|

Laser Type:

|

Nd: YV04 Solid Laser

|

|

Wave Length

|

355nm

|

|

Power

|

Minimum Power to Liquid Level≥300mW

|

|

COATING SYSTEM

|

|

|

Coating Mode

|

Intelligent Position Vacuum Recoating

|

|

Normal Layered Thickness

|

0.1mm

|

|

Rapid Build Layered Thickness

|

0.15mm

|

|

Precise Build Layered Thickness:

|

0.05mm

|

|

Special Build Layered Thickness:

|

0.05mm~0.20mm

|

|

OPTICAL & SCANNING SYSTEM

|

|

|

Light Spot(diameter @1/e2):

|

0.06-0.8mm(Varible Beam)

|

|

Scanning Mode

|

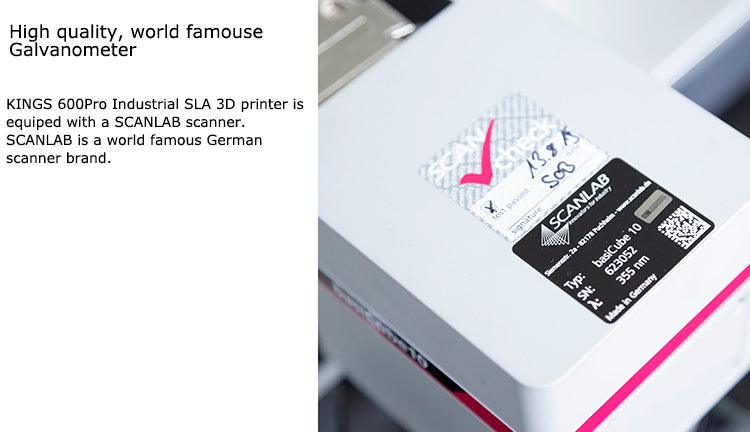

Germanic Galvanometer Scanner

|

|

Parts Scanning Speed:

|

Maximum 15.0m/s

|

|

ELEVATOR SYSTEM

|

|

|

Vertical Resolution Ratio

|

0.0005mm

|

|

Repeat Positioning Accuracy

|

±0.01mm

|

|

RESIN TANK

|

|

|

First Tank Weight:

|

about 76kg

|

|

Forming Material:

|

Photosensitive Resin

|

|

Resin Heating Method:

|

Bottom Heating with Silicone Rubber

|

|

CONTROL SOFTWARE

|

|

|

Machine Control Software

|

KING3D Control Software

|

|

Device Software Interface

|

3D Design Software, STL File Format

|

|

INSTALLATION CONDITION

|

|

|

Current Source

|

200-240VAC 50/60Hz, Single Phase,10A

|

|

Ambient Temperature

|

20-26ºC

|

|

Relative Humidity

|

<40%,Frost Free Knot

|

Printing Materials:

Committed to innovation, independent research, and development, self-production and marketing, high-quality achievements. KINGS has an independent 3D printer laboratory and independent research and development system and has core technical personnel. Now we have established a perfect integrated production and marketing model of 3D printing material design, research, and development, production and sales. The company has realized the strict quality guarantee of 3D printing materials from research and development to production and the diversification of materials provides customers with more options.

|

Resin Model

|

Material Features

|

Resin Color

|

|

ABS-Like resin(Finish product similar to ABS)

|

||

|

KS408

|

Delicate surface, temperature resistance 45ºC, good toughness

|

White

|

|

KS608

|

Temperature resistance 65ºC, moistureproof, good strength, and accuracy in humid condition

|

Yellow

|

|

KS408B

|

Delicate surface, good solidity, temperature resistance 55ºC

|

Brown

|

|

PMMA like resin(Finish product similar to PMMA)

|

||

|

KS158T

|

Transparent, moistureproof & shrinkage proof, temp resistance 60ºC, toughness 15% lower than KS408

|

Transparent

|

|

Silicone Like Resin(Finish product is soft)

|

||

|

KS198S

|

Low viscosity, high flexibility, and high accuracy

|

White

|

Our Advantages

True-to-CAD Accuracy and Surface Finish

360 degree printing regardless of the constructure complexity of the design. Fabricates small and medium-sized parts up to 300 mm x 350 mm x 350 mm with 0.05 mm accuracy, the highest among our printers, and with surface roughness as low as 0.05 μm. These standard tolerances out perform those of injection-molding and can even compete with CNC.

Outstanding Printing Speeds and support batch printing

Equipped with a top of the line galvanometer optical system by ScanLab Germany, the Kings-3035 SLA 3D printer displays top scanning speed and enhances 30-50% production efficiency significantly.

Wide Choice of Materials

A selection of over 10 different photosensitive resins with unique characteristics for functional prototypes and low-volume manufacturing, and helps to save more than 50% cost.

No noise, Low power Consumption, More Eco-friendly

No noise and maximum power consumption is less than 2KW. There will be no dust or heavy metal pollution, thus offers the workers a healthier environment.

Easy to operate, 24-hours unmanned intelligence

The Kings control software is very user-friendly. The automatic production needs no guard, which saves up to 60% of the labor cost compared to CNC machining