Описание

Shenzhen Piocreat 3D Technology Co, Ltd was established in2015 and is an early manufacturer of 3D printer equipment. Basedon our independent R&D and self-innovation, we completely ownindependent intellectual property rights on our products. We focuson the R&D, production and sales of 3D printers for advertising sign,jewellery and dentistry, and large-size additive manufacturing. Relying on years of professional 3D prnting R&D and manufacturngtechnology precipitation, through continuous innovation, we provideexcellent 3D printers and solutions services for customers in adver-tising, jewelry, medical and dental, automobile, hand-made model and other industries

We have a large-scale production base covering an area of 10,000square meters, complete R&D, manufactuning and after-salesservices, and strong technical strength. We have advancedlarge-scale R&D centers, 3D printing laboratones, new matenalsresearch institutes and modern production lines in China, with24-hour uninterrupted professional testing lines and strict qualitycontrol systems to ensure product quality from the source

Quality depends on professionalism, and brand depends onservice. "We will rely on professional development, based in Chinafacing the world, and becoming a world-renowned enterprise in theapplication of 3D printing industry

|

Technical

|

FGF Fused Granulate Fabrication

|

|

Printing Size

|

1200x1000×1000mm

|

|

Machine Size

|

2200x1780×2250mm

|

|

Feeding structure

|

Screw Rod Extrusion

|

|

Nozzle

|

Single Nozzle

|

|

Nozzle Diameter

|

0.6-6mm

|

|

Printing Layer

|

0.2-1.5mm

|

|

Hotbed Tempature

|

≤150℃

|

|

Power Voltage

|

AC220V

|

|

Rated Power

|

6500W

|

|

Particles Diameter

|

2-5mm

|

|

Printing Material

|

PLAV PETG/PVC/ABS/PC/PAVHDPE/TPU/EVA PC+ABS, PA+Fiber, WPC: MQP-S+PA12; EVAbased foamboard

|

|

Nozzle Tempature

|

≤450℃

|

|

slicer software

|

Creality Print

|

|

Printing speed

|

80-100mm/s

|

|

Files Format

|

STL/OBJ/AMF/3DMF

|

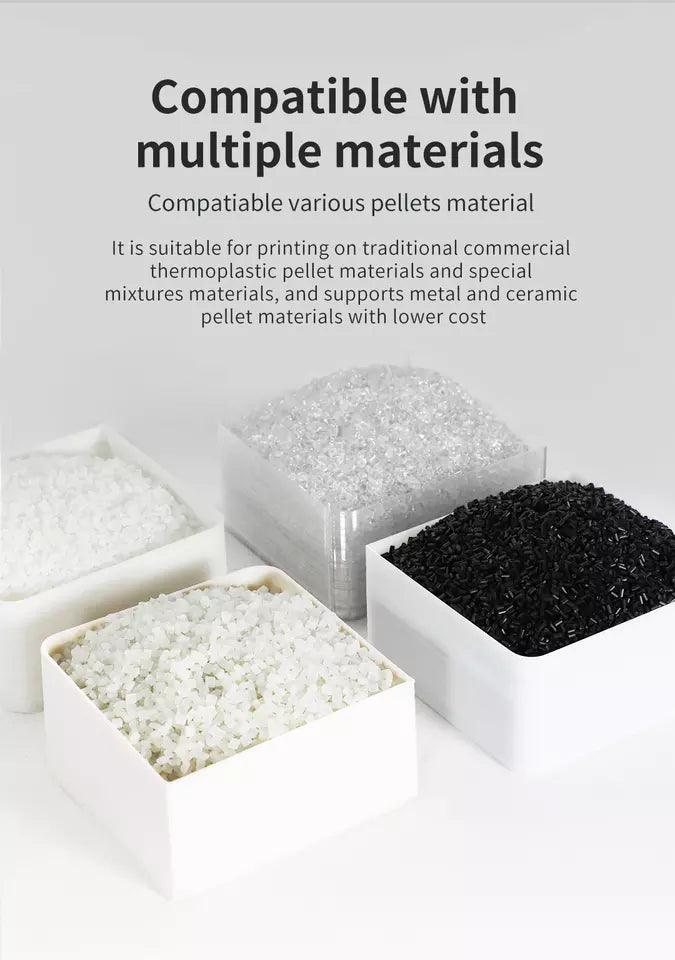

Compatible with multiple materials

Compatiable various pellets materialIt is suitable for printing on traditional commercialthermoplastic pellet materials and specialmixtures materials , and supports metal and ceramicpellet materials with lower cost

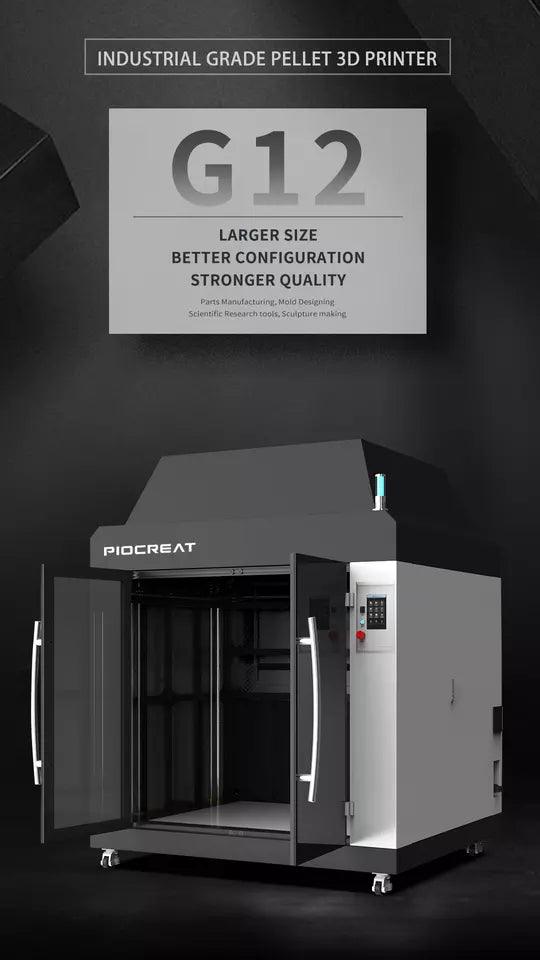

Super Large Format

Printing size 1200x1000x1000mmCan meet the demands of printing large scaleindustrial parts and the end products

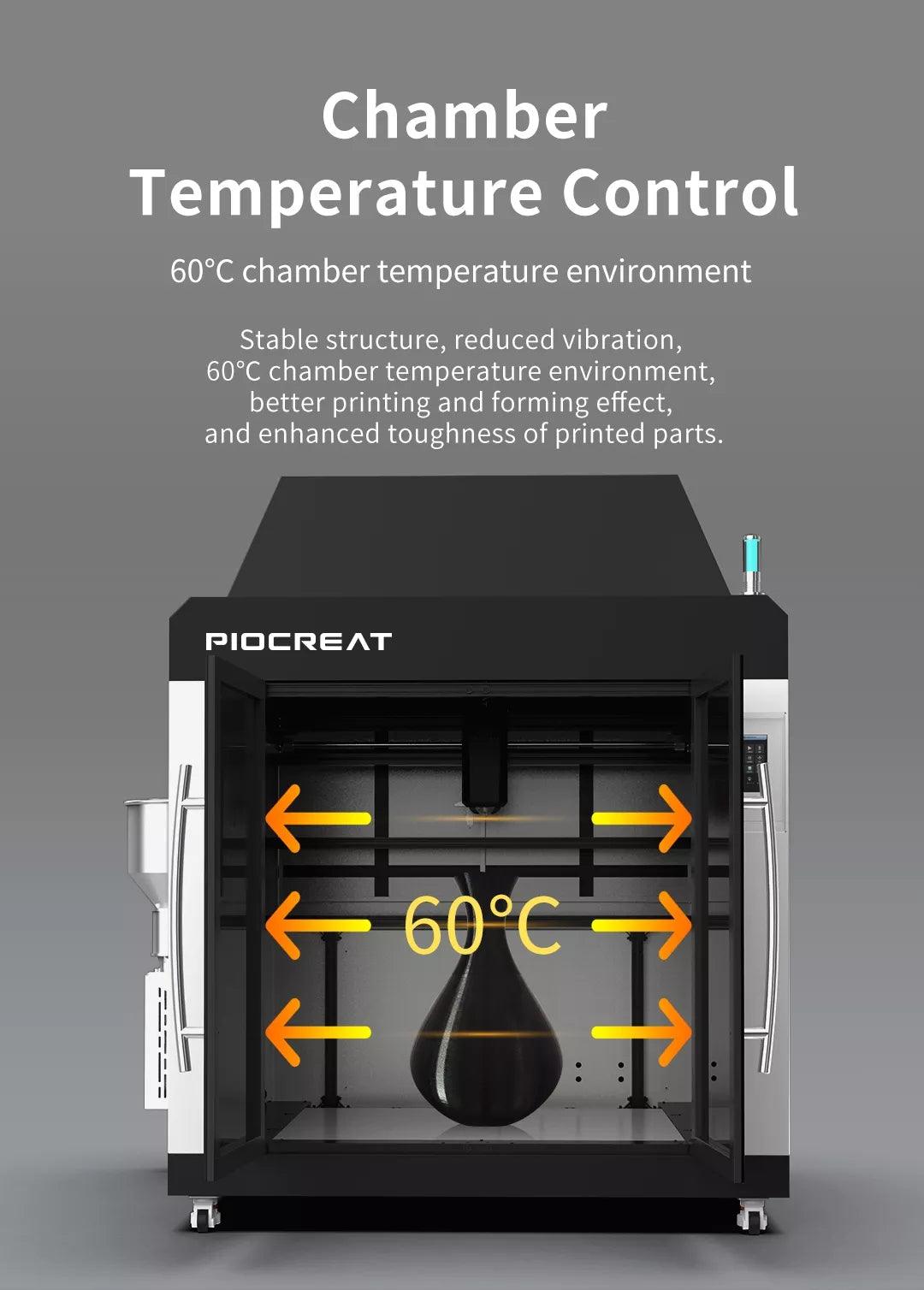

Chamber Temperature Control

60C chamber temperature environmentStable structure reduced vibration60 " C chamber temperature environmentbetter printing and forming effect ,and enhanced toughness of printed parts

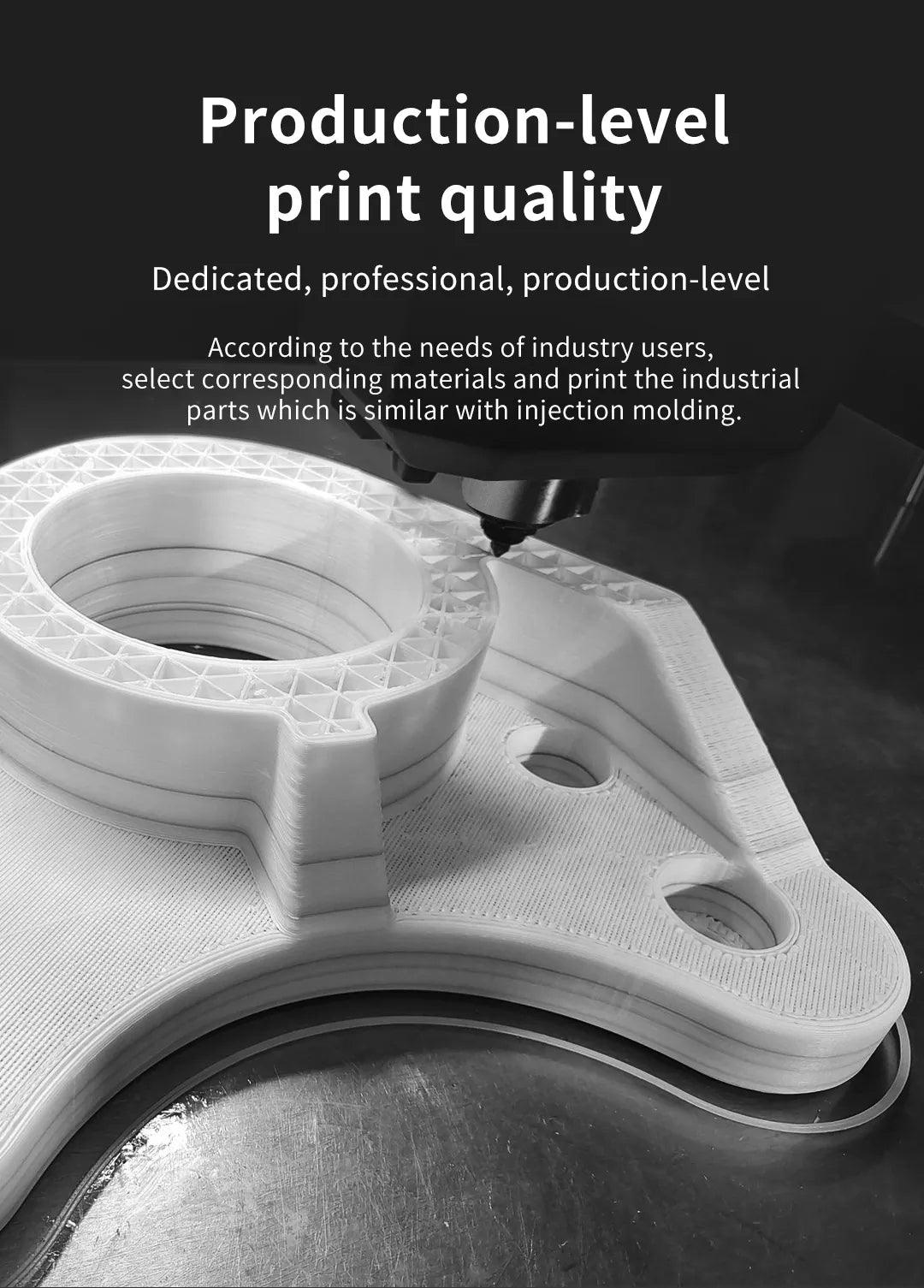

Production-level print quality

Dedicated , professional , production-levelAccording to the needs of industry users ,select corresponding materials and print the industrialparts which is similar with injection molding

Screw nozzle

Self developed screw nozzle designSelf developed screw nozzle designwith diameter 0 . 6-6mm , Max Temperature 450C ,Consumables melt thoroughly and squeeze out smoothly

Auto Smart Leveling

Multi-point auto leveling systemMulti-point auto leveling systemto ensure it does not warp when printing ,and the printing forming rate up to 99%

Rapid Heating Platform

Excellent and stable heating platformSilicon Heating Design , Heating up quickly .Reduce waiting time for printing , Convenient printing ;The power density per square is 0 . 48W / cm ;it is heated to 150 % C and air-fired for 5-8 minutes