I. Problem description:

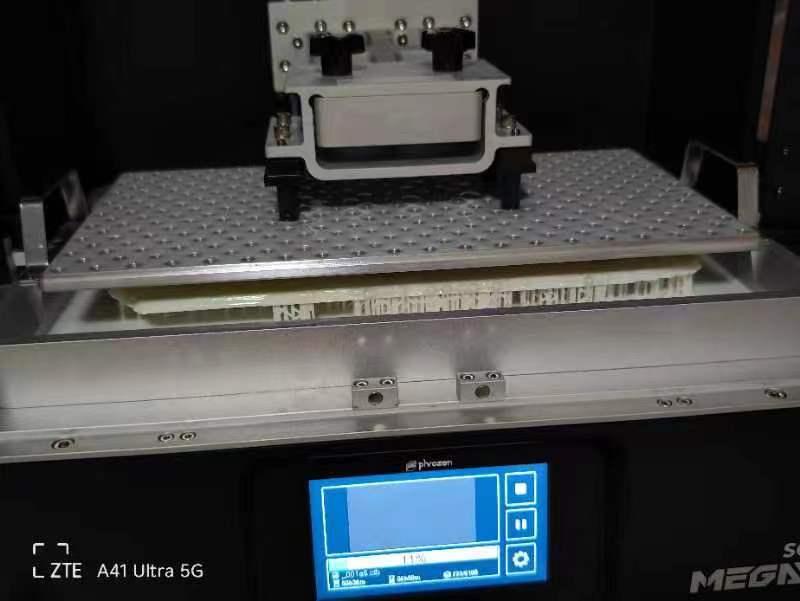

The base plate of the printed model is detached from the machine forming table

Ii. Solutions:

1. Check whether the exposure time at the bottom is sufficient

2. Check whether the surface of the forming table is too smooth

3. Check whether the printing speed is too high

Third, the solution

1. Under exposure at the bottom, the model will be detached from the molding table. The improvement plan is to increase the exposure time of the bottom, but I suggest that in order to avoid wasting the resin, you can print the test model first and observe the adhesion. Normally, there is a little resistance when shoveling down or when you replace the resin, you can use UVTOOLS software to directly test the exposure of the bottom and normal layer and observe the data to obtain the best parameters.

2. The molding table also needs to be cleaned after the completion of printing. A long time of printing and exposure will make the surface of the molding table adhere to a layer of curing resin, and because the surface texture of the molding table is no longer rough, the resin can not be well adhered to. For this purpose please place the forming table in alcohol soak and sand the surface.

3. If the layout of the printed object is too large and heavy, when the speed is too fast, the tension on the model bottom plate will increase in the unit time, resulting in the model bottom plate falling off. In view of this, the speed can be reduced and the model can obtain a longer stress distribution time in the unit time.