Solution:

1. Re-leveling

Use one piece of A4 paper. If soft magnetic steel plate is used, four pieces of A4 paper shall be leveled again.

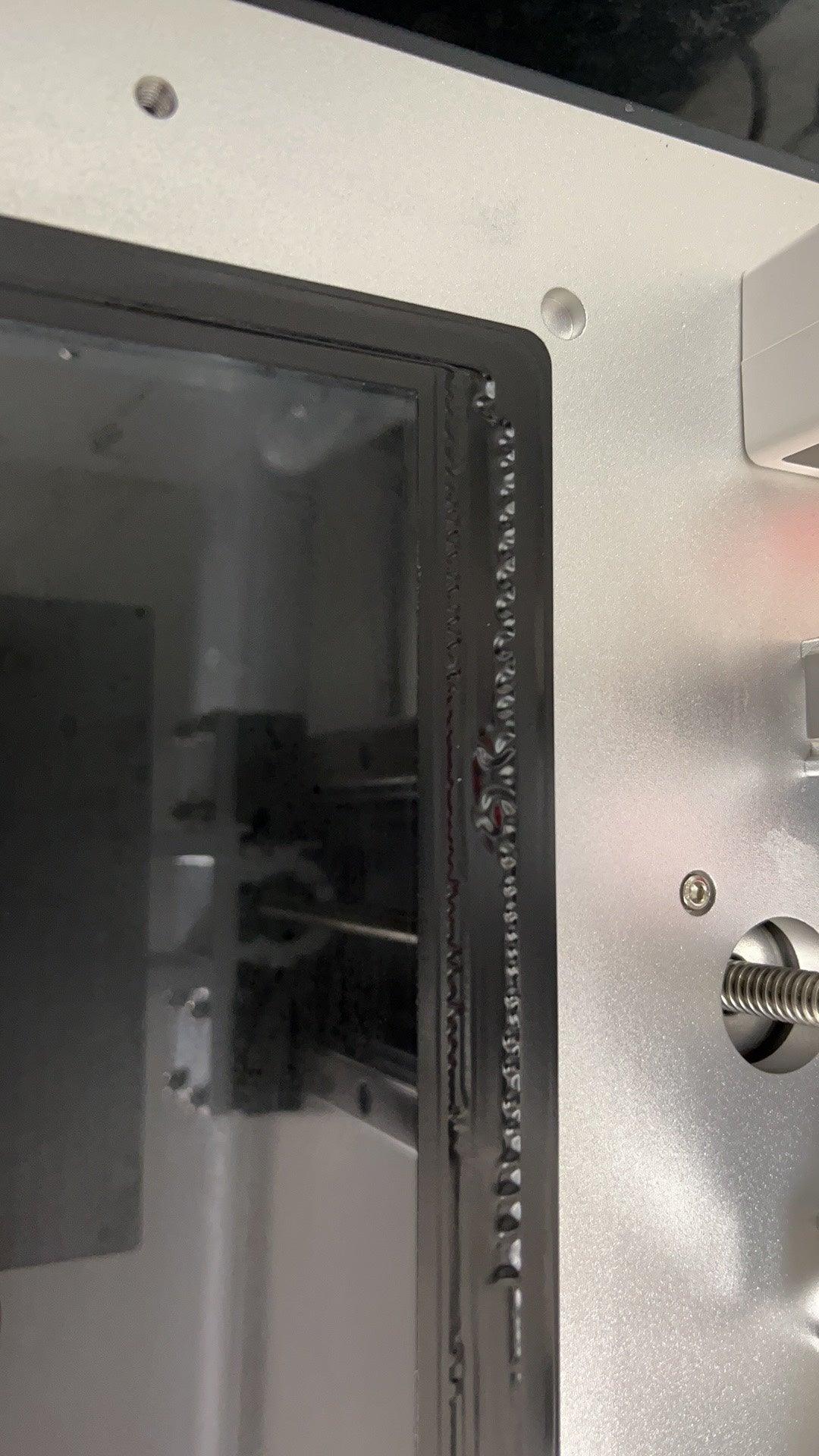

2. Check whether there is abnormal solidification substance at the bottom of the feed chute

If residual resin is solidified at the bottom of the tank, abnormal overpressure sound will also occur when the carrier platform falls to the bottom.

It is recommended to recycle the resin into the resin bottle first (it is recommended to use a filter screen) and check the status of the bottom of the feed tank and whether the release membrane is abnormal.

3. Reduce the lifting speed

If the resin is thicker and the temperature is lower (most of the resin thickens with the decrease of temperature), the liquid level pressure will increase, and the Z axis will make noise when the resistance is large.

It is recommended to adjust the printing parameters related to the Z-axis operation. The adjustment contents are as follows:

Bottom lifting speed: 40 mm/min

Lifting speed: 40 mm/min

Bottom return speed: 80 mm/min

Return speed: 80 mm/min