Description

|

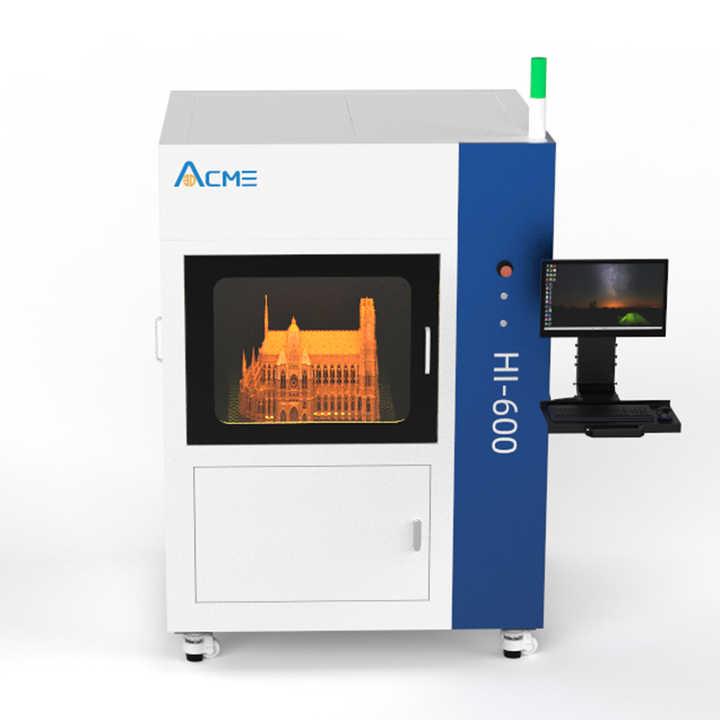

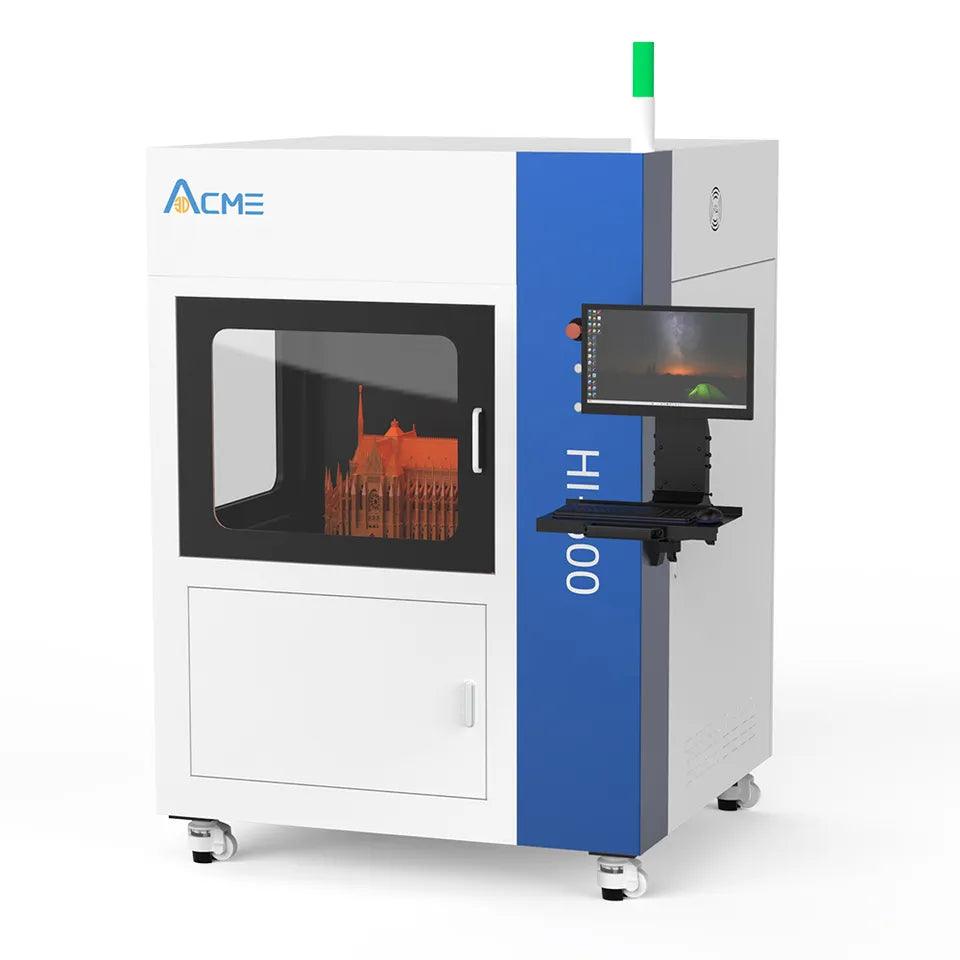

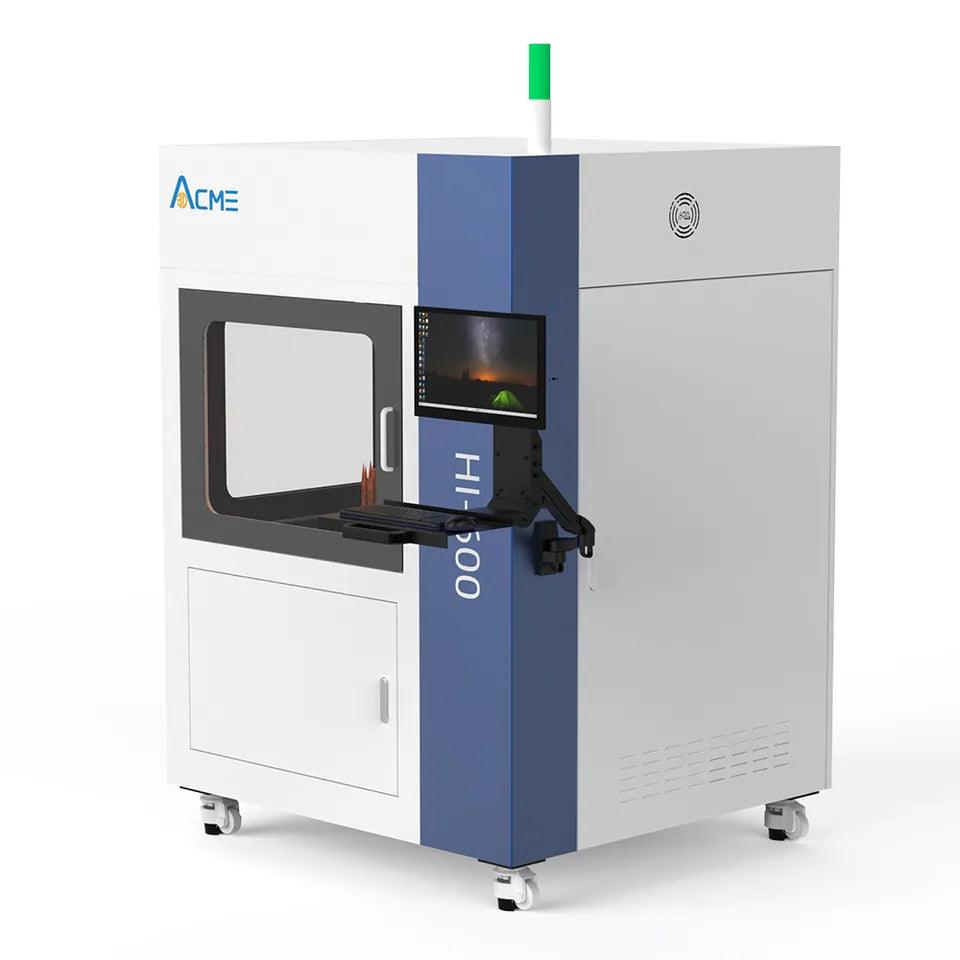

Model

|

HI600

|

|

Print size(LxWxH)

|

600X600×400mm

|

|

Machine size(LxWxH)

|

1390X1290X1965mm

|

|

Technology

|

SLA

|

|

Laser QTY

|

DPSSL(Diode Pump Solid State Laser) Nd: YVO4

|

|

Machine Weight

|

1

|

|

Wattage

|

1100KG

|

|

Coating Method

|

350W

|

|

Laser Wavelength

|

Vocuum Adsorption

|

|

Laser Wattage

|

354.7nm

|

|

Layer Thickness

|

3w

|

|

Normal Layer Thickness

|

0.05mm-0.15mm

|

|

Fast Layer Thickness

|

0.1mm

|

|

Pricision Layer Thickness

|

0.15mm

|

|

Resin Container Volume

|

220kg

|

|

Spot diameter

|

0.12-0.6mm

|

|

Scan Mode

|

Higt speed Galvo

|

|

Part Scan Speed

|

Proposed 6m/s

|

|

Part Jump Speed

|

Proposed 10m/s

|

|

Proposed print speed

|

100-300g/h

|

|

Platform

|

Integrated Platform

|

|

reset accuracy

|

±0.01mm

|

|

model max weight

|

30kg

|

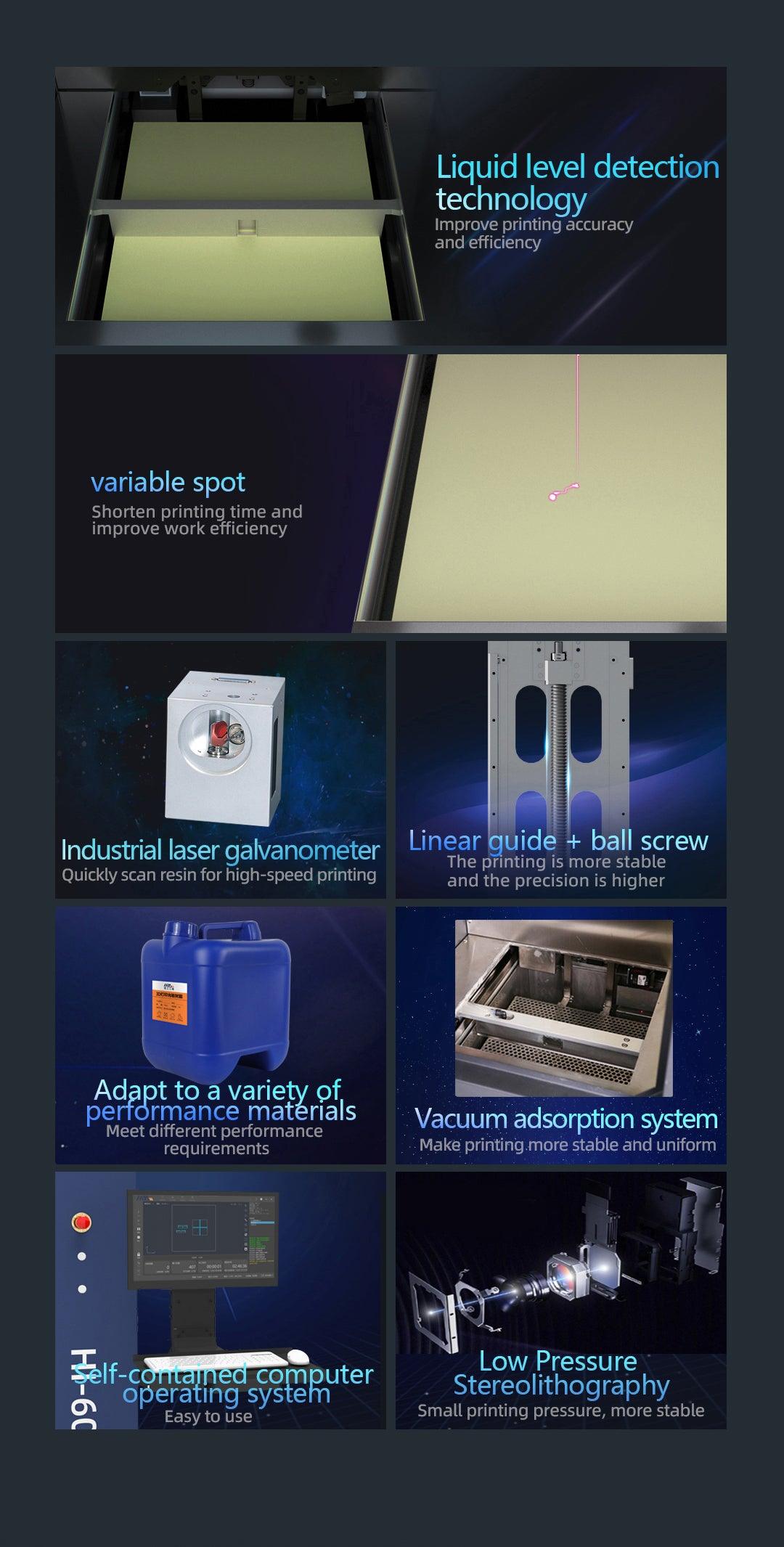

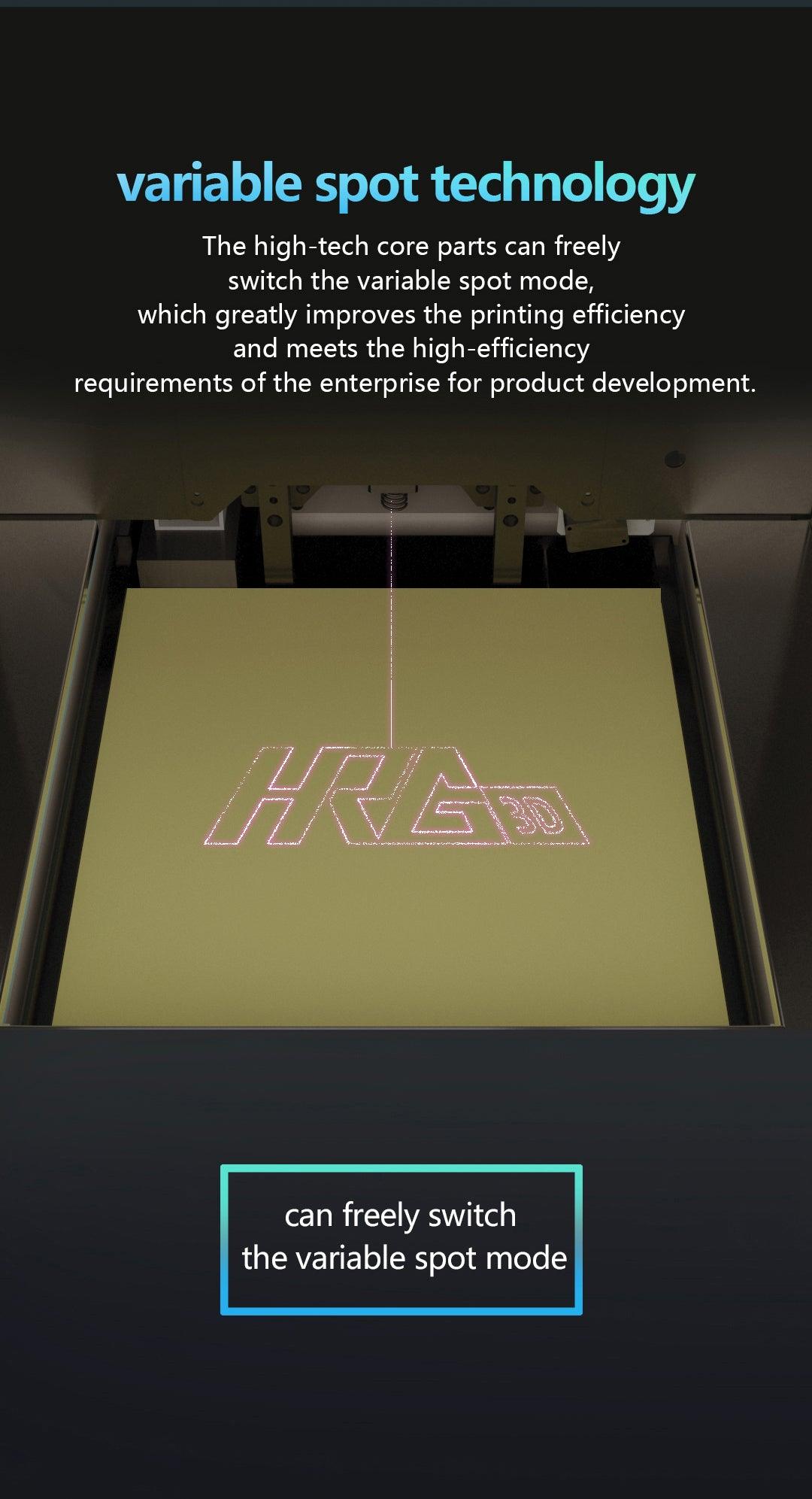

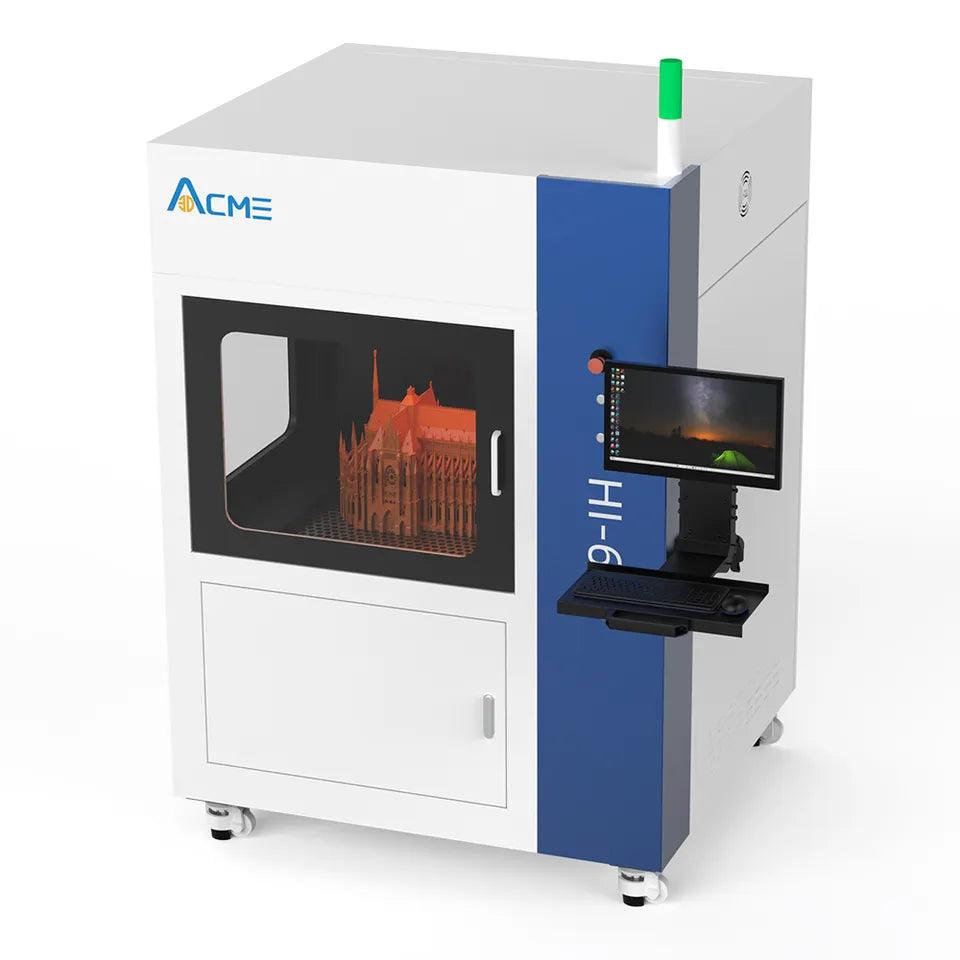

variable spot technology

The high-tech core parts can freelyswitch the variable spot mode ,which greatly improves the printing efficiencyand meets the high-efficiencyrequirements of the enterprise for product development

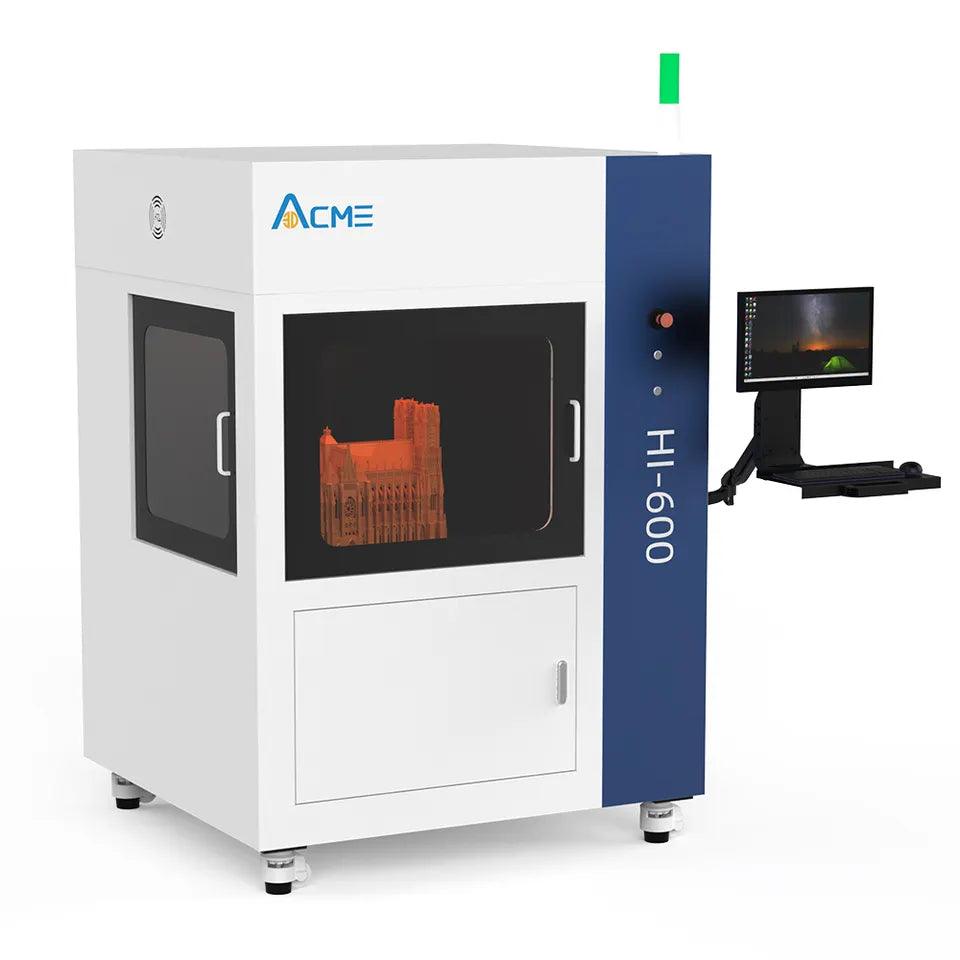

Vacuum adsorption system

Double-pump adsorption vacuum scrapercomputer controls the adsorption force ,which can increase or decrease the adsorption forceto make printing more stable and uniform( comparison of three models

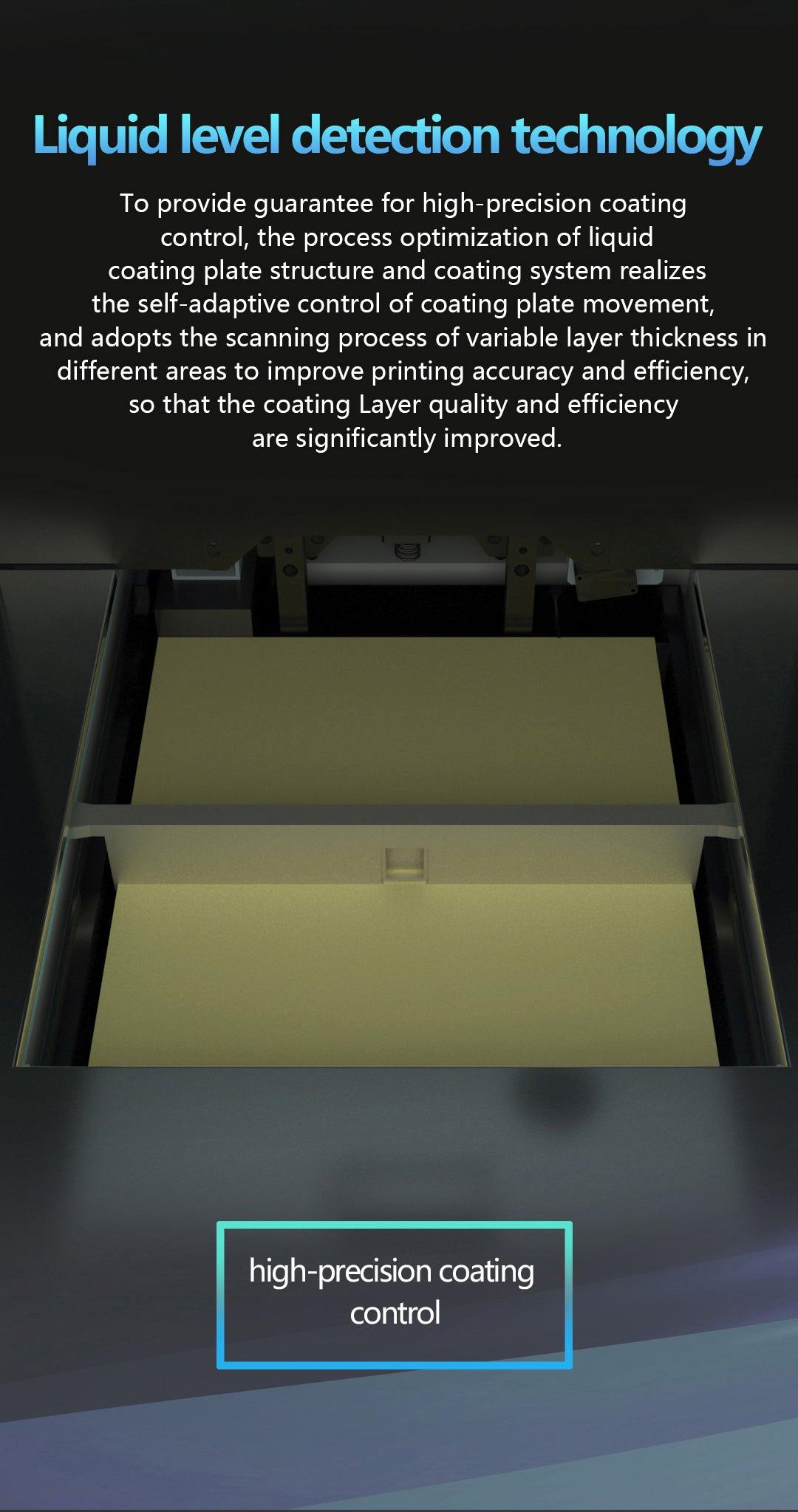

Liquid level detection technology

To provide guarantee for high-precision coatingcontrol , the process optimization of liquidcoating plate structure and coating system realizesthe self-adaptive control of coating plate movement ,and adopts the scanning process of variable layer thickness indifferent areas to improve printing accuracy and efficiency ,so that the coating Layer quality and efficiencyare significantly improved

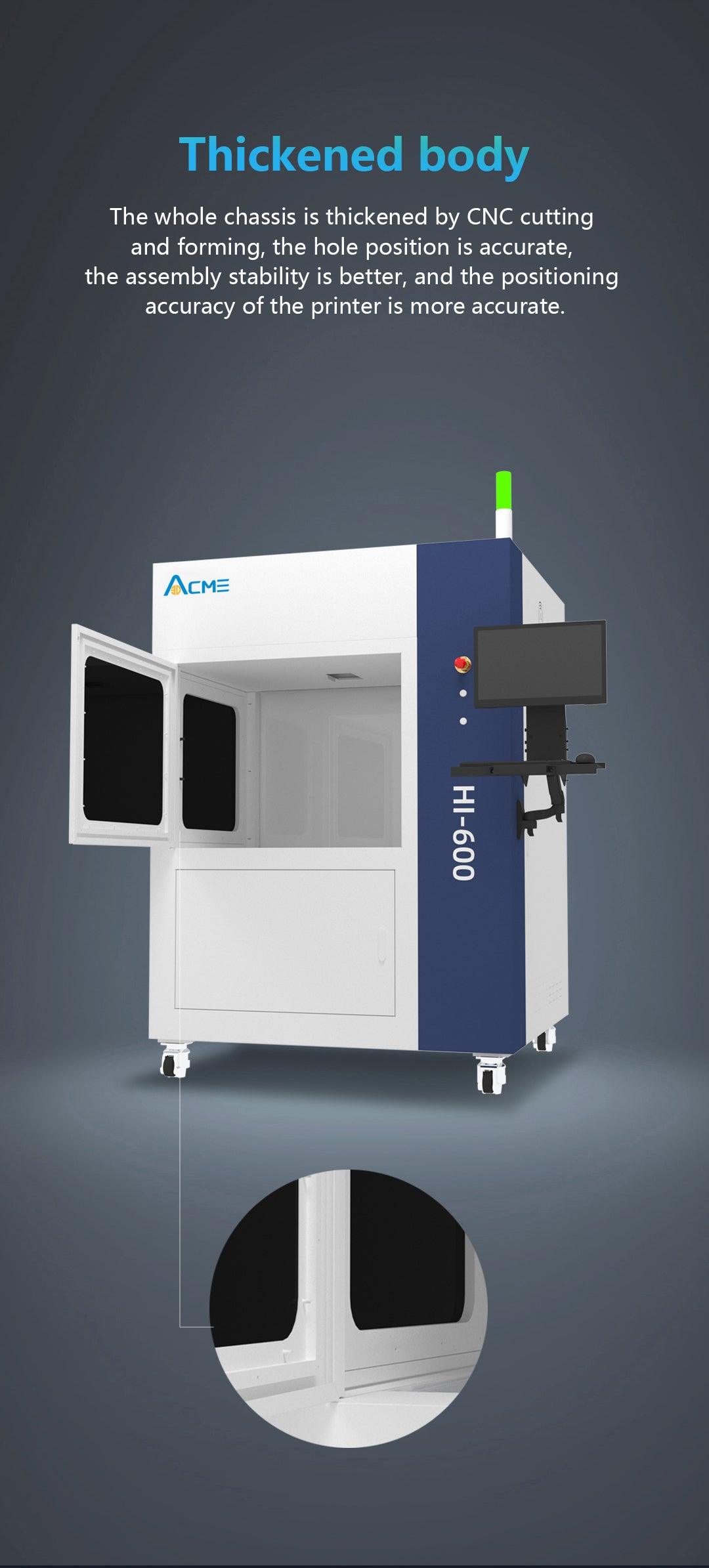

Thickened body

The whole chassis is thickened by CNC cuttingand forming , the hole position is accuratethe assembly stability is better , and the positioningaccuracy of the printer is more accurate

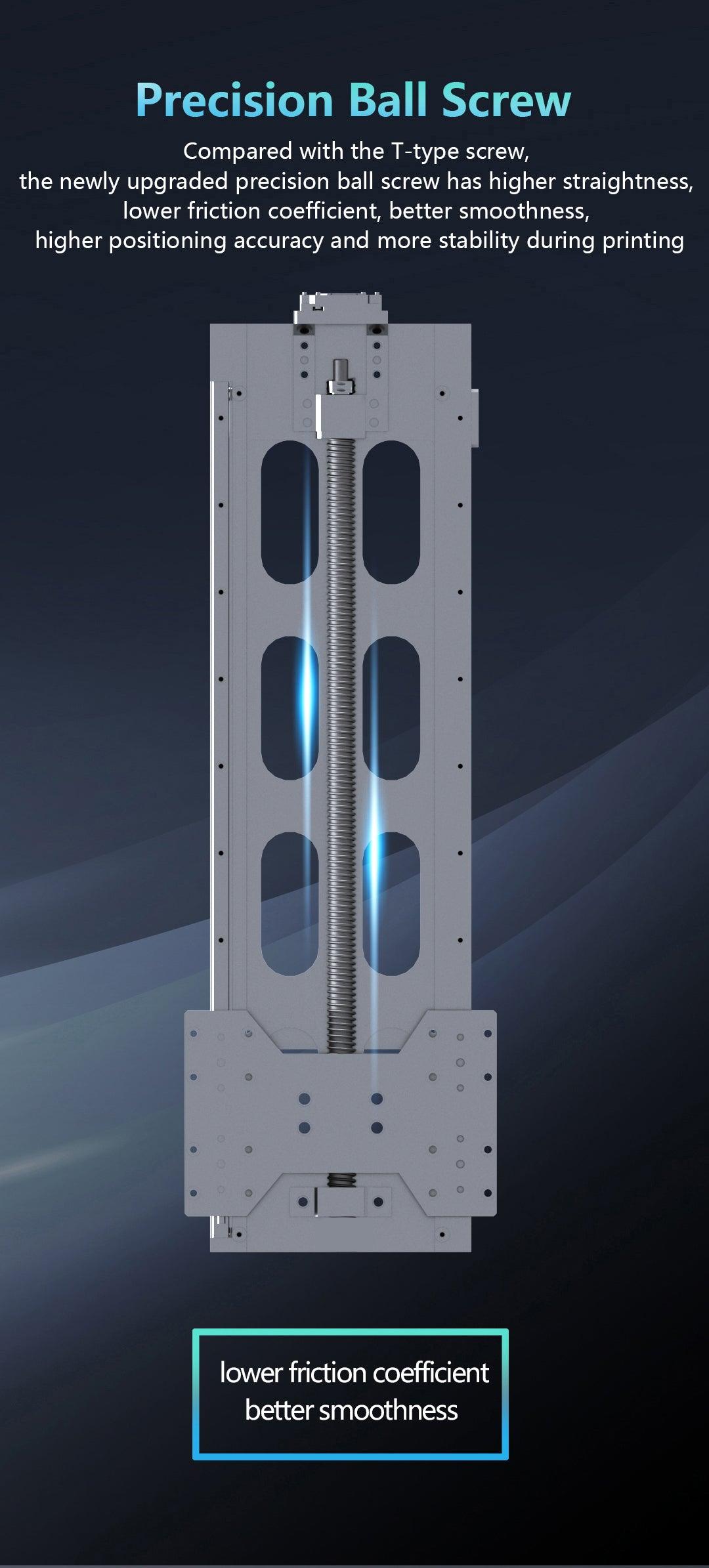

Precision Ball Screw

Compared with the T-type screw ,the newly upgraded precision ball screw has higher straightness ,lower friction coefficient . better smoothnesshigher positioning accuracy and more stability during printing

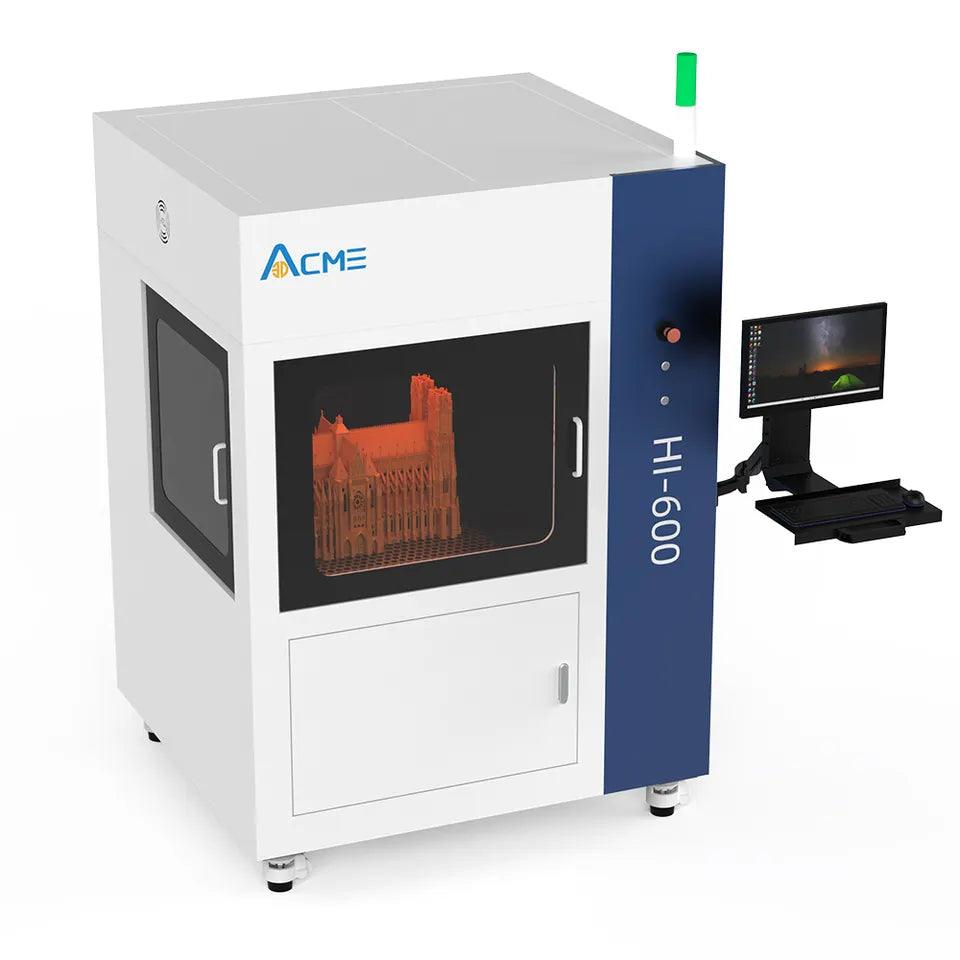

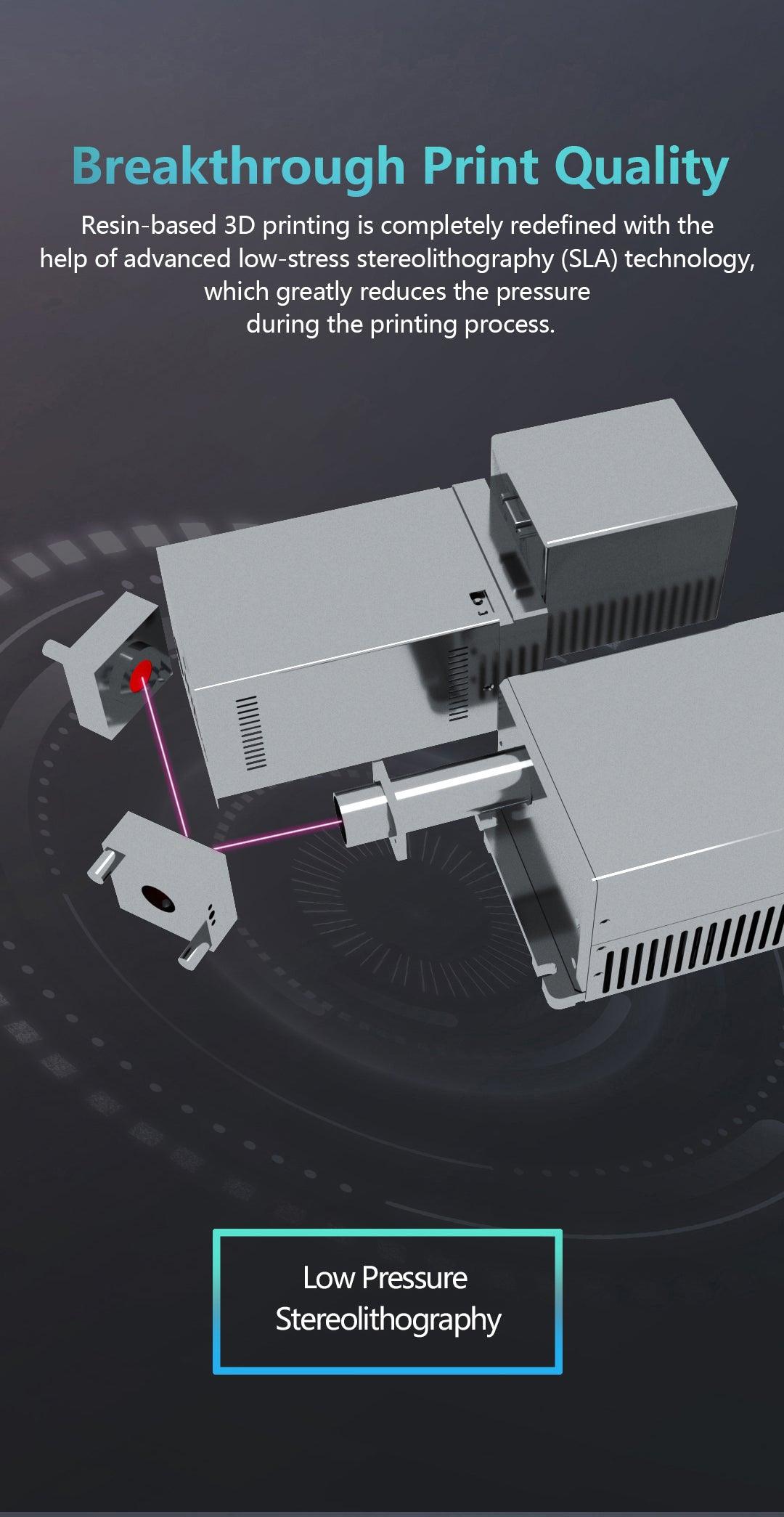

Breakthrough Print Quality

Resin-based 3D printing is completely redefined with thehelp of advanced low-stress stereolithography ( SLA ) technology ,which greatly reduces the pressureduring the printing process

storage resin tank

The super thick stainless steel trough is used to prevent rust ,peeling and oxidation , and the equipment is durable

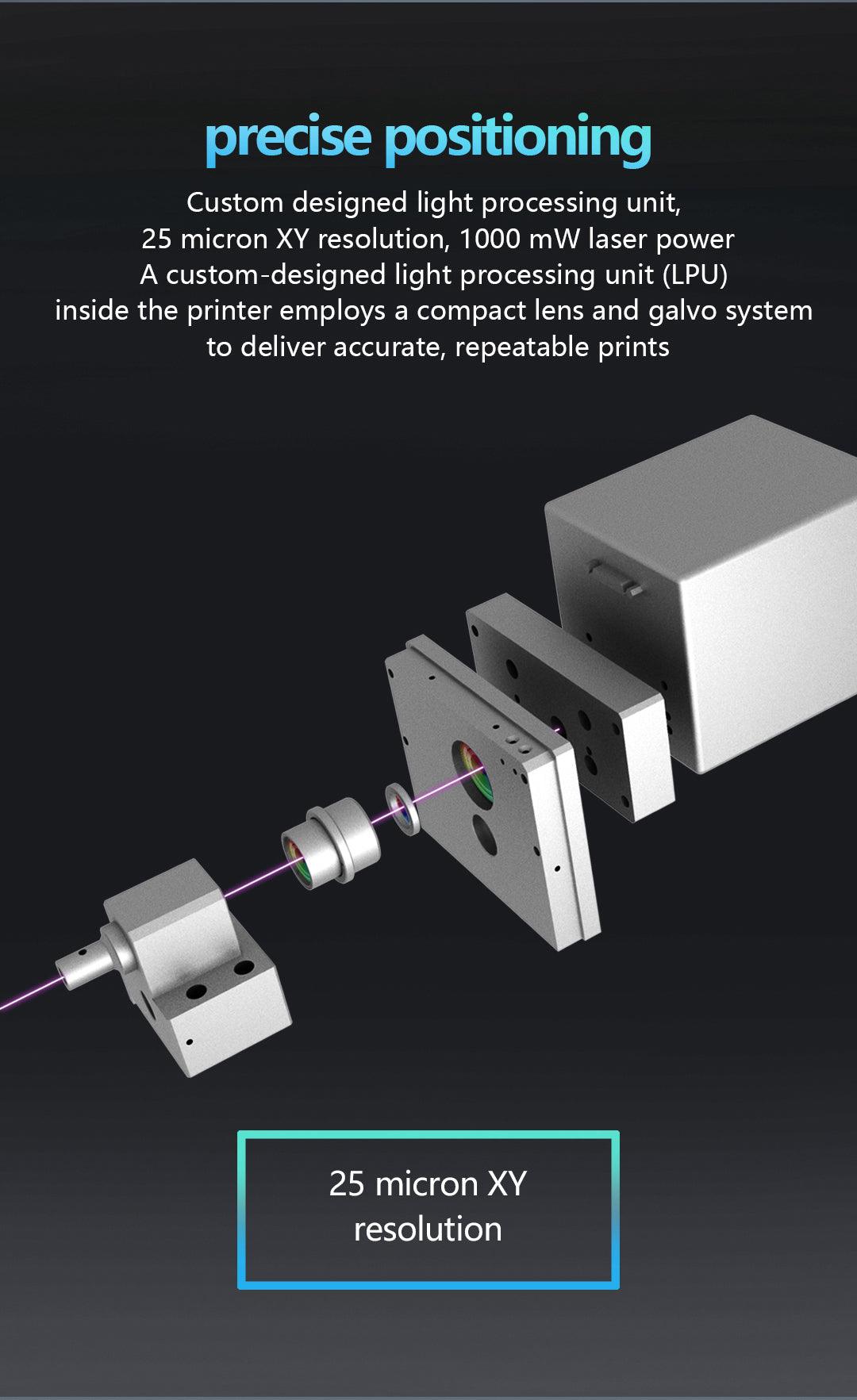

precise positioning

Custom designed light processing unit ,25 micron XY resolution , 1000 mw laser powerA custom-designed light processing unit ( LPU )inside the printer employs a compact lens and galvo systemto deliver accurate , repeatable prints

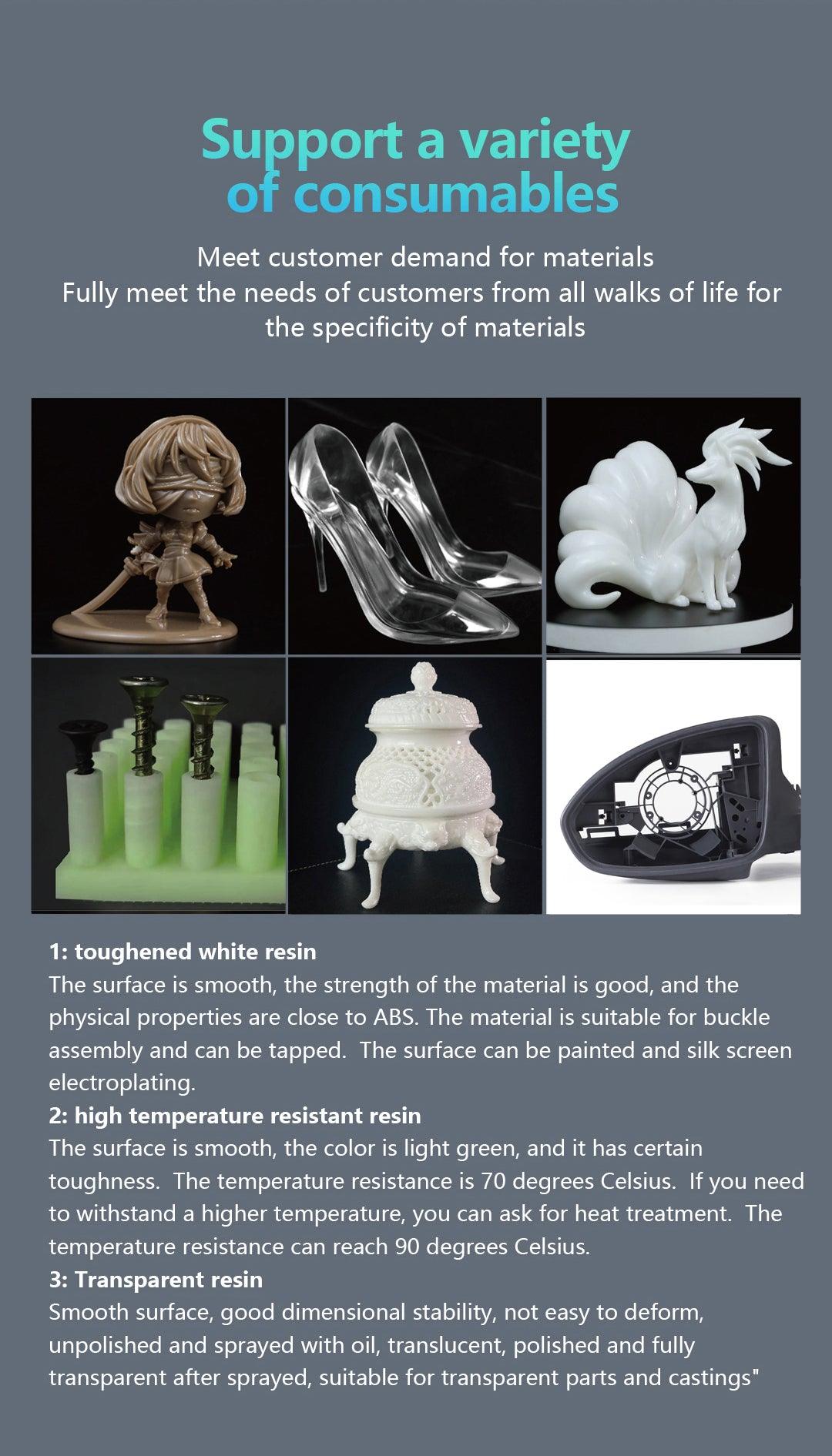

Support a variet of consumables

Meet customer demand for materialsFully meet the needs of customers from all walks of life forhe specificity of materials