Description

KINGS SLA 3D printers are widely applied by shoe manufacturer, mould factory, automobile manufacturer, college / research institute, construction company, etc., who come from various industries, like Shoe / Mould / Prototype / Toys / Cartoon / Architecture / Arts & Crafts / Jewelry / Dental / Appliance / Workshop / Education / CNC / Automotive / Furniture / Design / Bicycle, etc.

Product Description

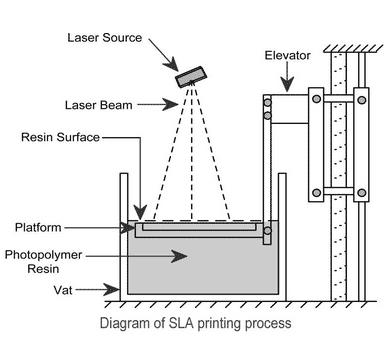

KINGS SLA(Stereolithography) 3D PRINTER is an additive manufacturing machine that works by focusing ultraviolet laser onto a vat of photopolymer resin. With the help of CAM or CAD software, UV laser is used to draw a pre-programmed design or shape on surface of the photopolymer vat. Photo -polymers are sensitive to ultraviolet light, so the resin is photochemically solidified and forms a single layer of desired 3D object. This process is repeated for each layer of the design until completed.

Principle of SLA

SLA process is the most studied, the most

advanced and the most widely used method

o frapid prototyping in the world(also the rapid

prototyping method adopted by our company).

SLA technology is the principle of computer

controlled laser beam scanning on the sur -face of the photosensitive resin material poi -nt by point. the thin resin layer(about a few tenths of a milimeter) in the scanned area produces photopolymerization reaction, whi -ch solidifies to form a thin layer of the part, the table down a layer of thickness so that the surface of solidified resin is coated with a new layer of liquid resin. the next layer is scanned and repeated until the whole prot -otype is finished since the photopolymerizati -on is based on light rather than heat, only lower power of laser source are needed at work.

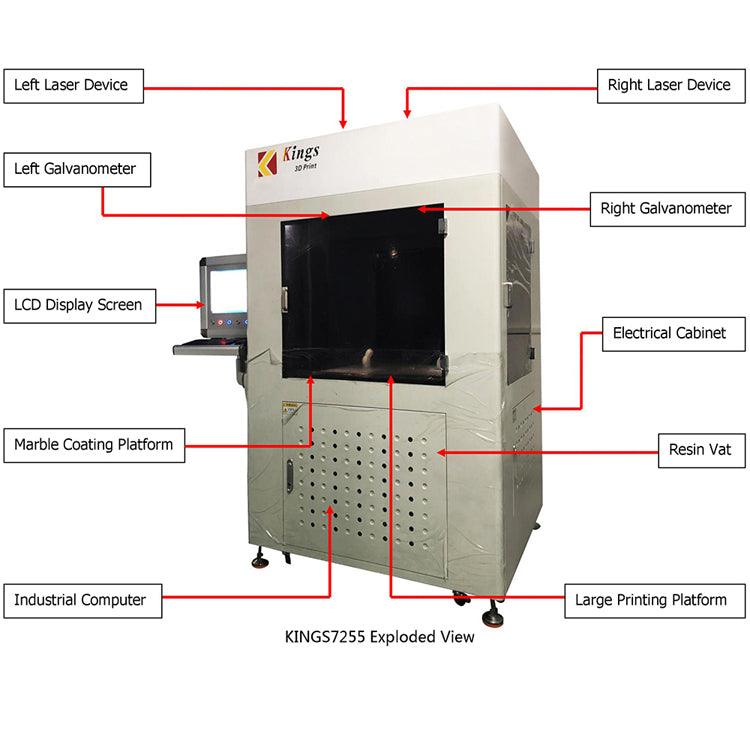

Features

1. Imported ball screw and linear guide rail guarantee high printing accuracy 0.01m;

2. Quick printing speed and batch production;

3. Complex structure model can be printed precisely and delicately;

4. Many photopolymer resin choices, like rigidity, detail, color, clarity and temperature tolerance;

5. Imported quality device: German galvanometer scanner & US laser device;

6. Variable light spot: bigger lighting area, higher printing speed;7. KINGS owned control software for simple & visual operation.

Main configurations

|

LASER SYSTEM |

|

|

Laser Type |

Nd: YV04 Solid Laser |

|

Wave Length |

355nm |

|

Power |

Minimum Power to Liquid Level≥300mW |

|

COATING SYSTEM |

|

|

Coating Mode |

Intelligent Position Vacuum Recoating |

|

Normal Layered Thickness |

0.1mm |

|

Rapid Build Layered Thickness |

0.15mm |

|

Precise Build Layered Thickness |

0.05mm |

|

Special Build Layered Thickness |

0.05mm~0.20mm |

|

OPTICAL & SCANNING SYSTEM |

|

|

Light Spot(diameter @1/e2) |

0.10-0.15mm |

|

Scanning Mode |

Germanic Galvanometer Scanner |

|

Parts Scanning Speed |

Maximum 10.0m/s |

|

ELEVATOR SYSTEM |

|

|

Vertical Resolution Ratio |

0.0005mm |

|

Repeat Positioning Accuracy |

±0.01mm |

|

RESIN TANK |

|

|

First Tank Weight |

about 270kg |

|

Forming Material |

Photopolymer Resin |

|

Resin Heating Method |

Bottom Heating with Silicone Rubber |

|

CONTROL SOFTWARE |

|

|

Machine Control Software |

KING3D Control Software |

|

Device Software Interface |

3D Design Software, STL File Format |

|

SOFTWARE SYSTEM |

|

|

Master Controller Operation System |

Windows 7 |

|

Network Type and Protocol |

Ethernet,TCP/IP |

|

INSTALLATION CONDITION |

|

|

Current Source |

200-240VAC 50/60Hz, Single Phase,10A |

|

Ambient Temperature |

20-26ºC |

|

Relative Humidity |

<40%,Frost Free Knot |