Description

Established in 2015, Shenzhen Piocreat 3D Technology Co., Ltd. owns the complete proprietary intellectual property rights of its products by virtue of independent R&D and innovation.The company focuses on the R&D, production and sales of 3D printers in advertising sign, dentistry, jewelry, other additive and subtractive manufacturing. Through years of accumulation in R&D and manufacturing technology in professional 3D printing and by means of continuous innovation, the company offers a variety of services to clients in advertising sign, jewelry, dentistry, medical care, automotive manufacturing, anime figurines, models and other industries. PioNext is a jewelry and dental 3D printer and resin brand owned by PioCreat 3D.

Covering an area of 10,000 square meters of large-scale production base, Piocreat 3D owns a complete system of R&D, manufacturing, after-sales and a strong technological edge. We own an advanced large-scale R&D center, 3D printing laboratory, new materials research institute and modern production lines coordinated by 24-hour uninterrupted professional testing line and strict quality control system to ensure product quality from the source.

Guided by "Quality is underpinned by professionalism, brand by service", Piocreat 3D will achieve to become a globally renowned brand in 3D printing industry by relying on professional development, basing ourselves on China and facing the world.

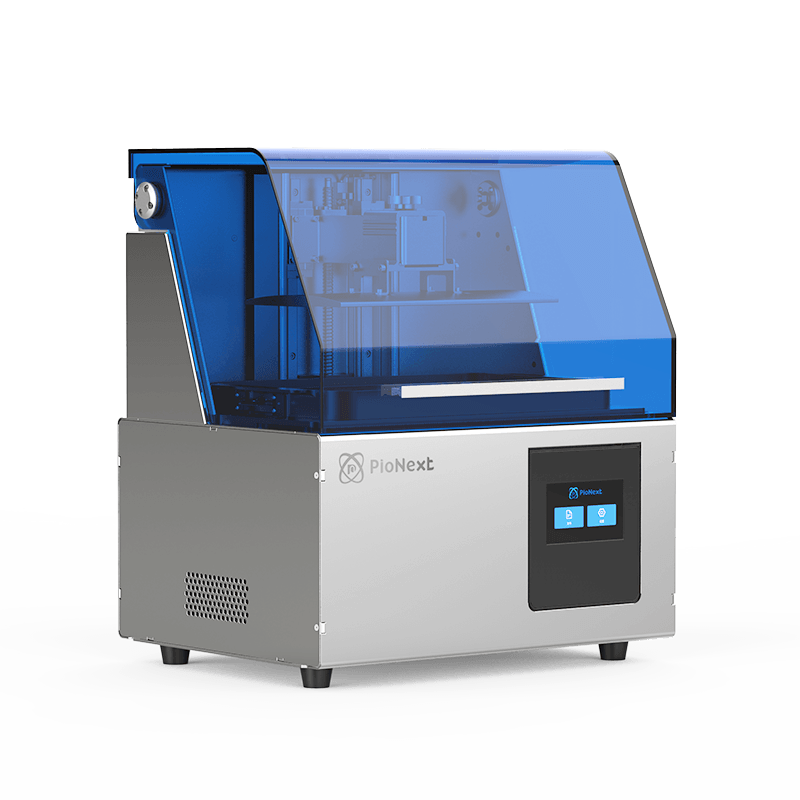

| Brand | PioNext |

| Product Model | D133 |

| Compatible systems | Windows7 and newer versions, MAC system |

| Slicing software | PioCreat Box |

| Supported file types | STL,OBJ |

| Connection | USB /Wi-Fi |

| Rated voltage | AC100-240V 50/60 HZ |

| Rated current | 4-5A |

| Rated power | 500W |

| Supporting resin | Ordinary rigid photosensitive resin; standard resin; elastic resin; high hardness and high toughness resin; biocompatible resin; casting wax resin; dental mold resin |

| Light source configuration | UV integrated lamp beads (wave length 405nm) |

| Resolution | 4K 13.3" monochrome LCD screen (3840*2160 pixels) |

| Touch screen | 5" touch screen |

| Safety standards | UL/ FCC/ CE/ ROHS/ UKCA/KC |

| Build volume | 293*165*300mm |

| XY axis accuracy | 0.075mm |

| Print speed | 1~4s/layer |

| Print layer thickness | 0.01-0.1mm |

| Lifting speed | 50-200mm/min |

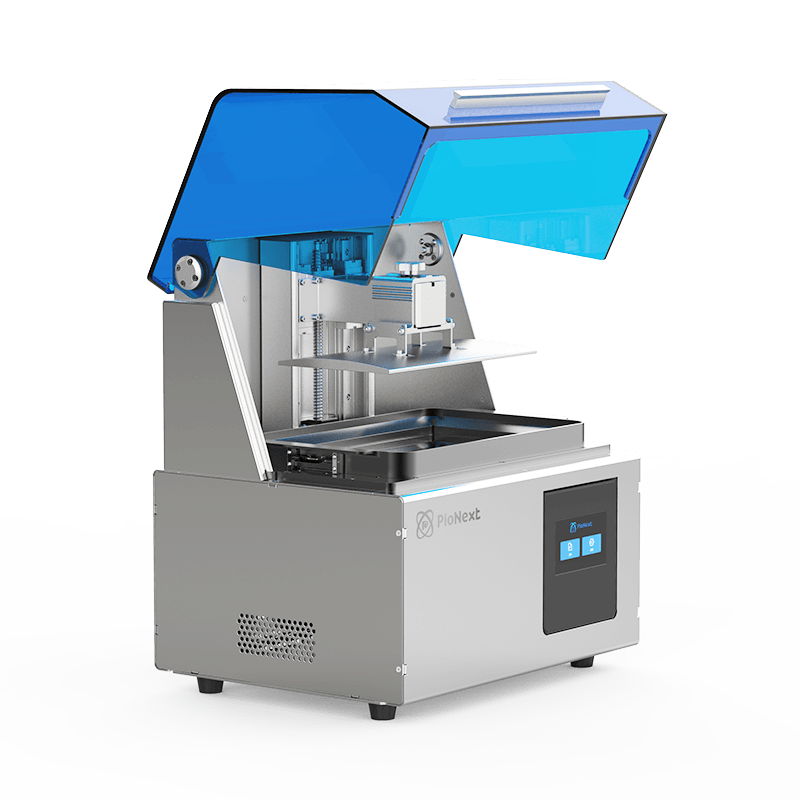

| Z-axis type | Dual linear guide + ball screw |

| Accessory kit | Manual/power adapter/resin vat/post-processing kit/automatic feeding box (optional) |

| Machine size | 480mm×405mm×770mm |

Print speed 30mm / h

5448 * 3060 pixels high resolution

277x156x100mm printing size

Humanized and innovative resin vat

Snap-in design , convenient and fast

Sandblasted and oxidatedforming platform surface

Eight big features Reshape your imagination

12 . 8 6K Monochrome screen 5448 * 3060 pixels Instant curing with high light intensity

Fast printing Max print speed : 30mm / h

New integral light source The light uniformity can be more than 95%

Multi-layer composite release technology Smaller release resistance ,higher success rate for printing

5.0 " full color HD screen Optimized interactive experience

Stable Z-axis structure Dual linear guide rail design + t ball screwDramatically improve positioning accuracy

New resin vat design Snap fits fixed trough , convenient and quick

Wireless transmission Offline printing Printing even offline

12 . 8 " 6K monochrome screen Print size : 277x156x100mm

Brand new large-size monochrome imaging displaytechnology With high light transmittance . Max usage life canbe Max 2000h . 6 times longer than that of the color screencompared with LCD color screen . The single-layer curing timecan be shortened to 1-4s to improve work efficiency amazingly.

5448 * 3060pixels high resolutionZero detail missing Printevery detail for you , capturing more subtle and complexdetails and perfectly print out a smooth , burr-free , and almostlayer-free model

Light uniformity 95% Innovative integral light source

high light source uniformity . no accurancy differenceof the printing model in the center and periphery ofthe printing platform

Stable Z-axis structure design Z-axis utilizes a dual linear slide rail and ball screw combinationstructure , bringing more stable movement and improving printingaccuracy reducing the layer pattern on printed model , and makingthe surface smoother

The snap-fits resin vat design

The snap-fits resin vat design makes the operation easierand more user-friendly and solves some of the inconveniencescaused by your daily use of the chuteBuilt-in liquid level reminder to prevent waste caused by excessive dumpingThe foot design of the trough allows you not to worry about scratches andcontamination of the release filmSnap fits fixing is convenient and quick , easy to move and place

Multi-laver composite release technology Smaller release resistance , higher success rate for printing

Wireless transmission Offline printing Printing even offline