Why Do My Prints Fall Off From Its Supports and Get Stuck to the FEP Film?

What’s Wrong with my Resin 3D Print?

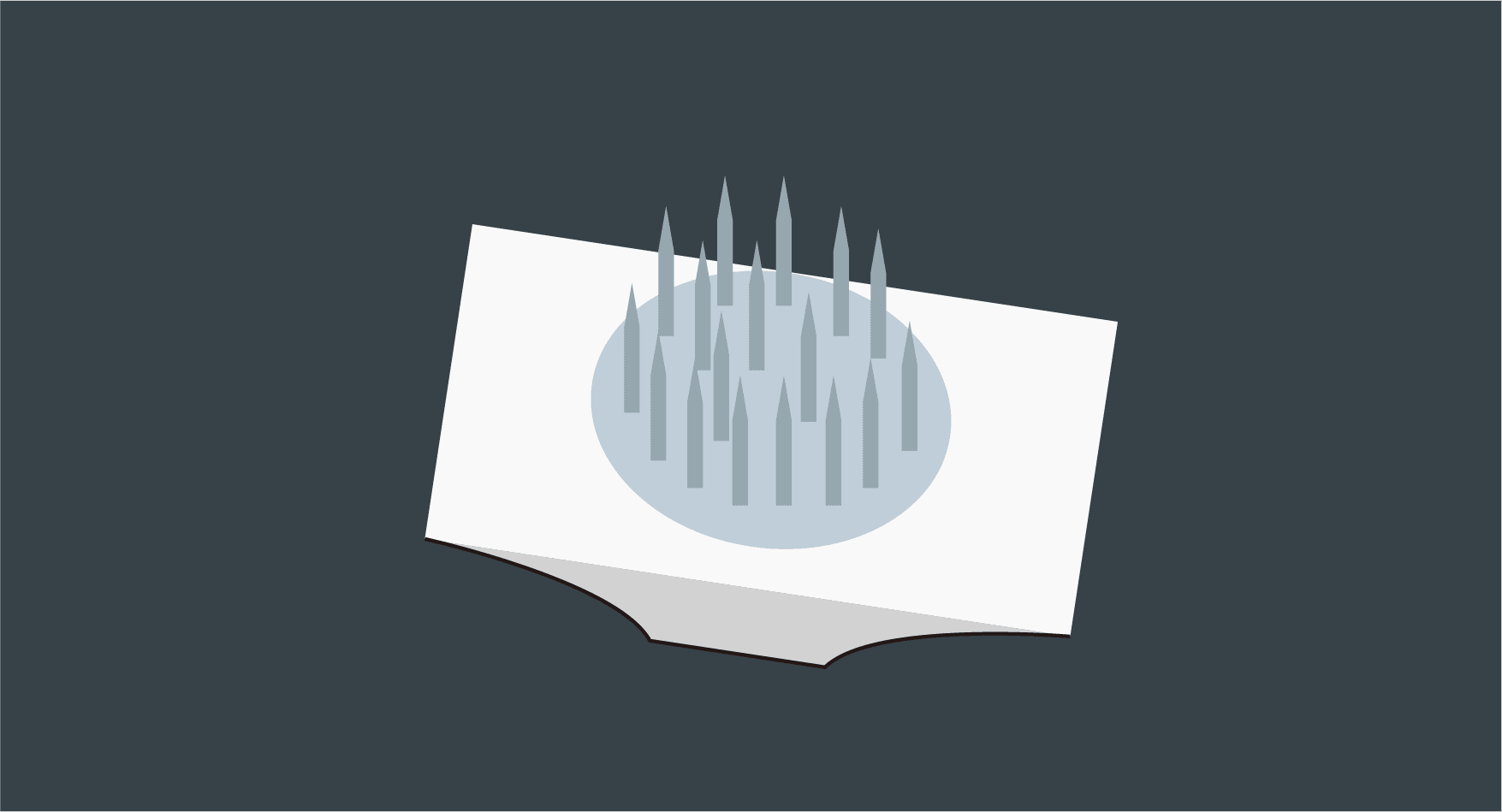

When you notice that the bottom layer sticks to the building plate, the supports have been printed out successfully, while the 3D model itself has fallen off from the supports during the middle of the print, dropping into the resin vat and is now stuck onto the FEP film.

What Causes the 3D Printing Issue?

This usually means that the supports are not strong enough and fail to hold onto the resin 3D model.

Before Moving On

Before you move on, please remove any resin residue in the vat. Check out this article to learn how to remove cured resin from my FEP film.

Troubleshooting the Model Falling Issue

Resolving this issue may require adjusting several settings as well as redialing your resin before continuing to adjusting the supports. The following steps are in the order of the most likely cause of the printing issue:

Adjusting the Resin Profile Settings:

- Check out the official resin profile and make sure you have dialed in the resin correctly.

- Increase normal layer exposure time by 10%.

- Lower the lifting speed to below 40mm/min.

- Make sure your light-off delay time is set according to this auto-calculator.

Adjusting the Support Settings:

- Increase the Upper Diameter and Support Density. For suggested values, please refer to this article.

- Avoid setting supports on a flat surface. Instead, rotate your model on both the X-axis and Y-axis.

- Avoid printing your model at an angle that may cause the formation of a suction cup as the model faces the resin vat. If that is the case, make sure to rotate your model or add drain holes to your 3D print.

- If it is a hollowed 3D model, make sure the wall thickness for small print is at least 1.5 mm, large print at least 2 mm, then add at least 2 drain holes that are at least 3 mm wide to the bottom of the 3D print.

If you're still facing this issue, please fill out the following form, and our engineering team will get back to you within two business days.

1. For suggested settings for setting supports in CHITUBOX Slicer Software, please refer to this article.

2. Light-off delay time is essential in resin 3D printing. With the correct settings, each layer will be printed in a much more stable manner, resulting in a better quality 3D print. Please refer to this article to learn more about light-off delay.