Descripción

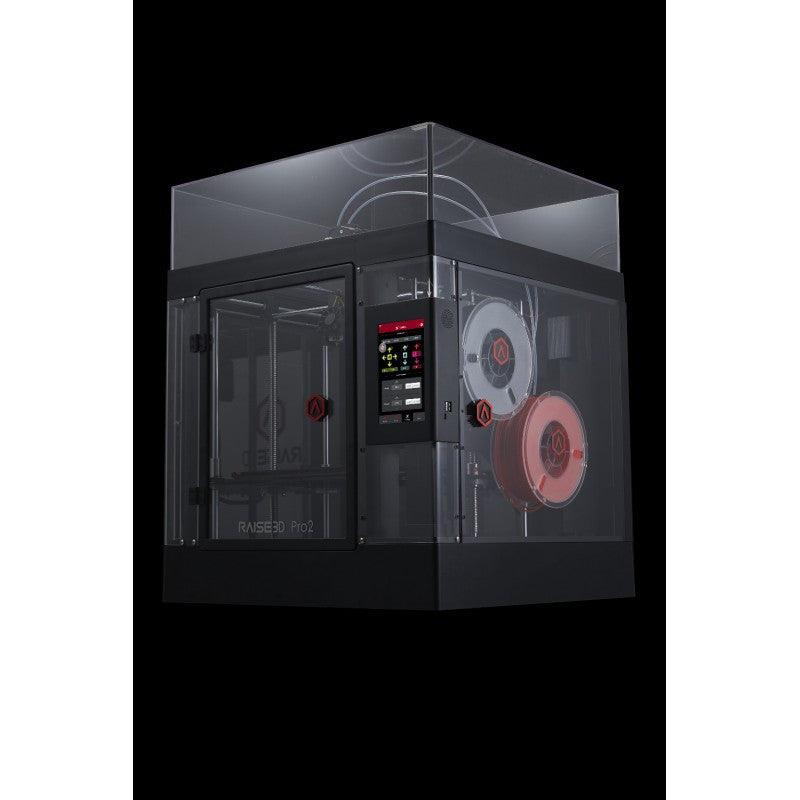

The Raise3D Pro 2 printer is made of an industrial grade of elements. Ideally suited for small lot production and prototyping. The printer allows long-lasting work with the most difficult materials. The Raise3D Pro 2 has two nozzles that allow you to print the most complex geometries.

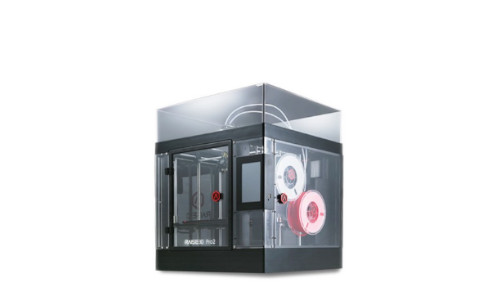

Raise3D Pro 2 3D printer

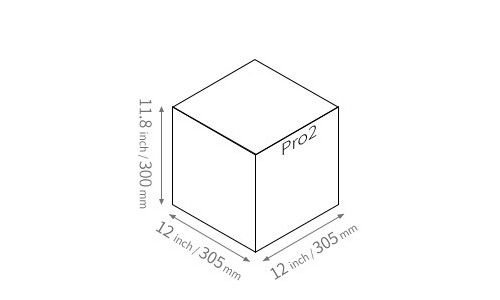

The Raise3D Pro 2 printer is mainly intended for small-lot production and for prototyping. It is made of high class industrial elements with a working area of 305 x 305 x 300 mm. Raise3D Pro 2 works in FFF tenchology (Fused Filament Fabrication), which involves printing fiber ductile thermoplastic material.

Raise3D Pro 2 - Double extruder

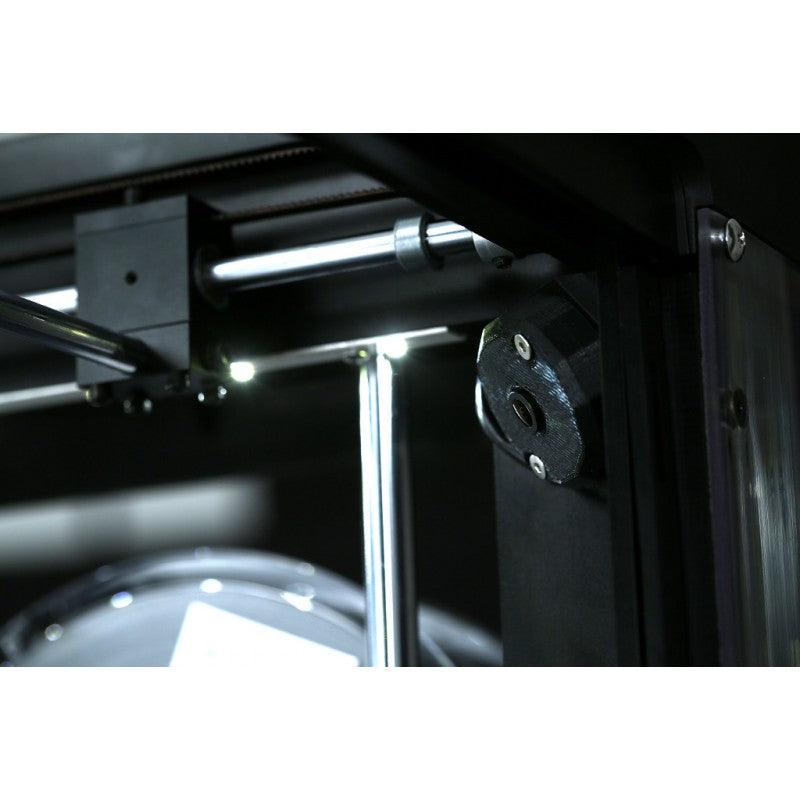

Raise3D Pro 2 has a double extruder with an electronic lifting system that allows printing of multi-material objects. Increases the speed of printing models and allows the use of water-soluble PVA support material. The head speed is 30 - 150 mm / s. During printing, the nozzle temperature is max. 300 ° C. Raise3D Pro 2 has the ability to replace the nozzle size 0.2 / 0.4 / 0.6 / 0.8 mm.

Raise3D Pro 2 - Construction

The Raise3D Pro 2 printer has an extremely large working area of 305 x 305 x 300 mm and a double extruder. This ensures the freedom to print a wide variety of multi-material 3D objects, while ensuring that these prints are precise and high quality. The printer has a 7-inch built-in touch screen and 2 USB 2.0 ports and 1 Ethernet port. Raise3D Pro 2 has a built-in 8 GB Flash memory.

Construction

- 24/7 Reliability

- Multiple fail safe systems

- Industrial grade components

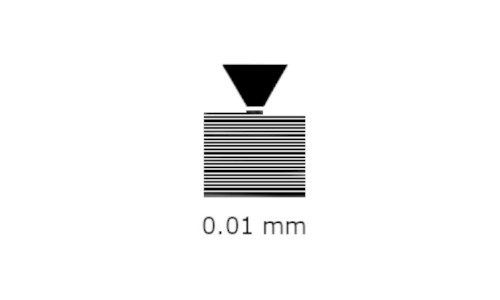

High Resolution

- Interchangeable nozzles (0,2 / 0,4 / 0,6 / 0,8 mm)

- Precise positioning (0.78125 micron positioning resolution on X/Y axis)

- Unmatched layer resolution (0.01 mm layer thickness)

IdeaMaker software

Efficient and free software for preparing prints developed by Raise3D has an excellent interface and the ability to repair STL files. Raise3D Pro 2 allows you to set the automatic raising or lowering of the layer height, which improves print quality and reduces printing time.

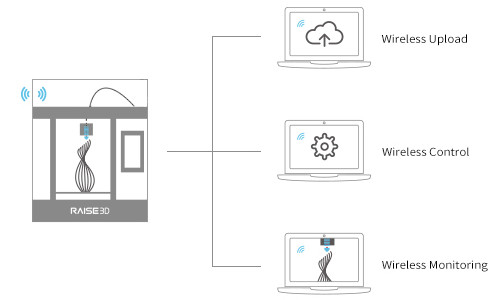

Remote user interface

A wireless connection to the 3D Pro 2 printer is available using the ideaMaker software. It allows wireless transmission, control and monitoring of printouts.

Creating your own settings

IdeaMaker software allows creating settings for various printers, filaments and models. Saved settings can be used for later projects or shared with others.

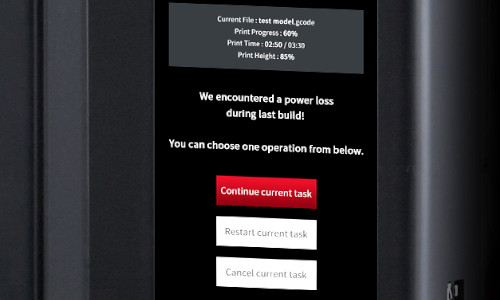

Resume printout

The Raise3D Pro 2 printer allows you to resume printing after power off. After restarting the device, the display will show the option to resume the previous printout.

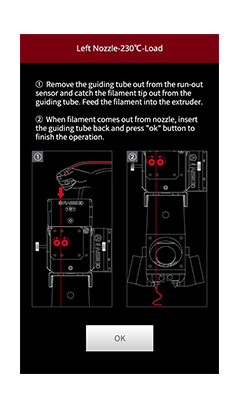

Filament end sensor

The filament end sensor will notify the user of the material being terminated on the spool. The print will stop until the new material is replaced. The sensor guarantees reliability and continuity of printing.

HEPA filters

The Raise3D Pro 2 printer uses HEPA industrial filters, which means that the device can be used in an office environment. The filter retains over 91% of particles that escape in other printers during printing.

RaiseCloud - 3D printing management

RaiseCloud is an online platform for remote project management. It allows remote control, monitoring and reporting of the entire printing process. It allows you to manage any number of users, printers and tasks in one place. Users can remotely control, monitor and modify project data.

Next Generation Motion Controller

Best in class reliability / Precise voltage control / Silky smooth movement / Superior thermal performance

- 400 MHz ARM Cortex-M7 32bit RISC FPU

- Industrial grade components

- Stand-alone motor driver

- 256 micro-steps driver system

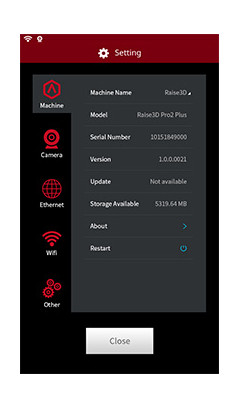

Intuitive service

Visual interface / Quick overview / Visual printing progress / Full adjustment control.

The Raise3D Pro 2 printer has a convenient, built-in high-resolution touch screen that allows you to view the progress of printing and allows full control of settings. Files for the printer can be read via USB and sent over WiFi. The built-in camera allows you to monitor the progress of work, the software provides the ability to remotely control the printer.

7 inch touch screen

Integrated setting control

Instructions

Visual model selection

The possibility of using many materials

Raise3D printers have been designed to ensure high material compatibility. To achieve the best performance and quality, select the appropriate print settings. For this purpose, the Raise3D Open Filament Program (OFP) was created. Filaments approved by Raise3D, which have been tested before, are sent to OFP. Print settings for such materials are included in IdeaMaker software to give users easier selection of the highest performance filaments.

PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Infused / Carbon Fiber Infused / Metal Fill / Wood Fill

Raise3D Pro 2 - Raise3D Pro 2 Plus

Raise3D printers are perfect for industrial and professional applications. These printers work in FFF technology, have a large work area with the possibility of closing the working chamber and a built-in touch screen. The double extruder allows you to work with multi-material prints, and the resume printing system after turning off the power will ensure continuity of work.

Raise3D Pro 2 printer

Raise3D Pro 2 Plus printer

Raise3D Pro 2 and Pro 2 Plus printers differ mainly in terms of the working field dimension and the external dimension. The Raise3D Pro 2 printer has a 305 x 305 x 300 mm working area, while the Raise3D Pro 2 Plus printer is larger and its working area is 305 x 305 x 605 mm. The external dimensions of the Pro 2 printer are 616 x 590 x 755 mm and 616 x 590 x 1107 mm for the Pro 2 Plus printer. Both printers work in FFF technology and have a double extruder with an electronic lifting system that allows printing of multi-material objects. Printers are mainly intended for small-lot production and for prototyping.

Data sheet

- Print Technology FFF

- Working area 305 x 305 x 300 mm

- Supported materials Nylon, PLA, ABS, PC, TPU, HIPS, PP, PVA, PET/PETG, Inne

- Nozzle size 0,2 / 0,4 / 0,6 / 0,8 mm

- Filament diameter 1.75 mm

- Nozzle temperature Max. 300°C

- Build Plate Heated aluminum build plate with magnetic holding

- Max Build Plate Temperature 110°C

- Connectivity WiFi, LAN, USB Port

- Software IdeaMaker

- File Types .stl, .obj

- Operating systems Mac OS X, Windows, Linux

- Power Universal 100 - 240 V, 50/60 Hz

- Printhead Dual-head with electronic lifting system

- Travel speed of the head 30 – 150 mm/s

- monitoring Live camera

- Ports SDCard x 1, USB 2.0 x 2, Ethernet x 1

- Onboard Flash 8 GB

- Touchscreen 7 inch Touch Screen

- XYZ Step Size 0,78125 / 0,78125 / 0,078125 mikron

- Build Plate Material Silicone

- Build Plate Leveling Pre-calibrated leveling

- Operating Sound 50 dB

- Power Supply Output 24 V, 600 W

- Network Ethernet, WiFi 802.11b/g/n 2,54/5 GHz

- Screen Resolution 1024 x 600

- Resume Print after Power Outage Second Generation

- Motion Controller ARM Cortex M7, 400 MHz FPU

- Logic Controller Freescale imx6, Quad Core 1 GHz ARM

- Memory 1 GB

- OS Embedded Linux

- Dimensions 616 x 590 x 755 mm

- Warranty 12 months