Descripción

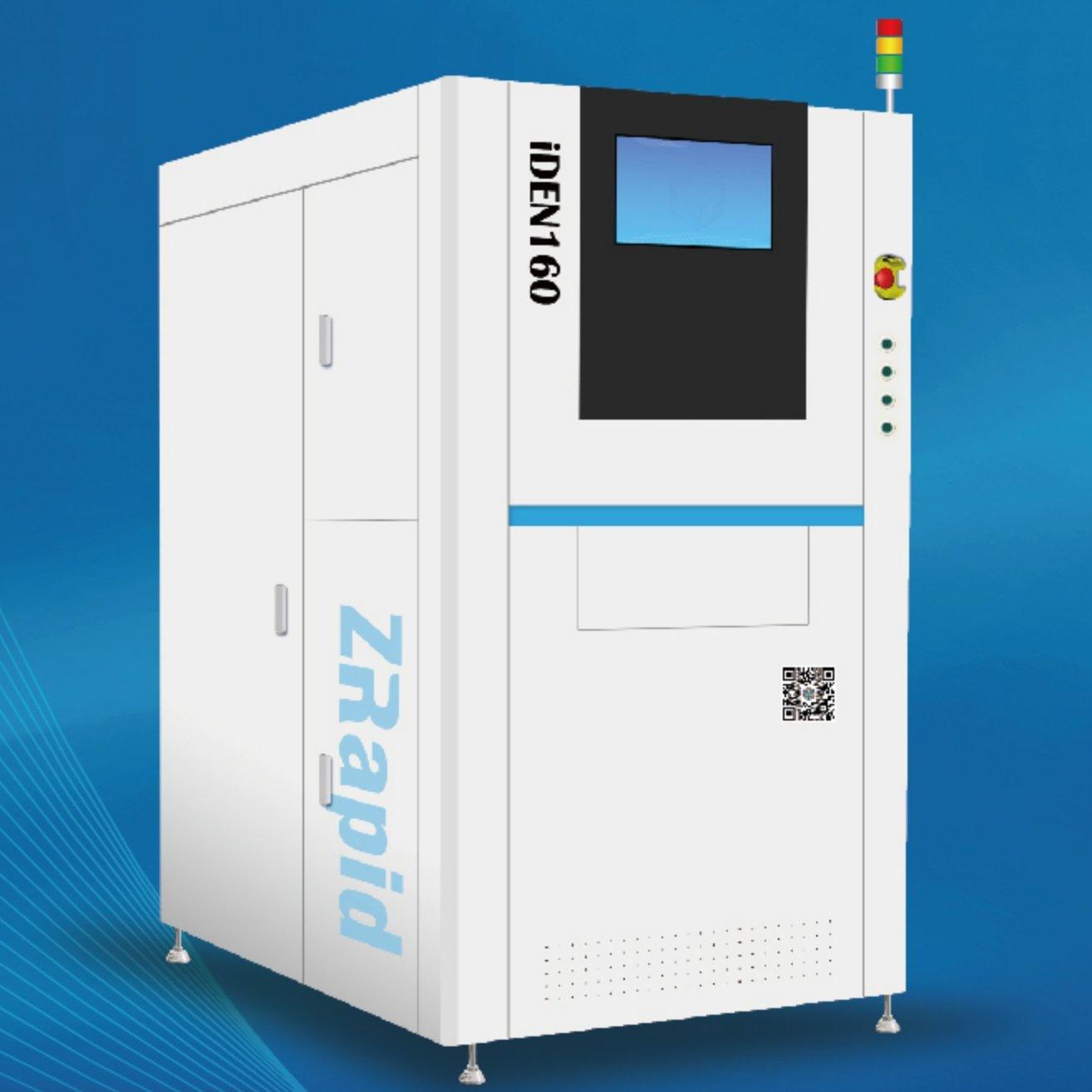

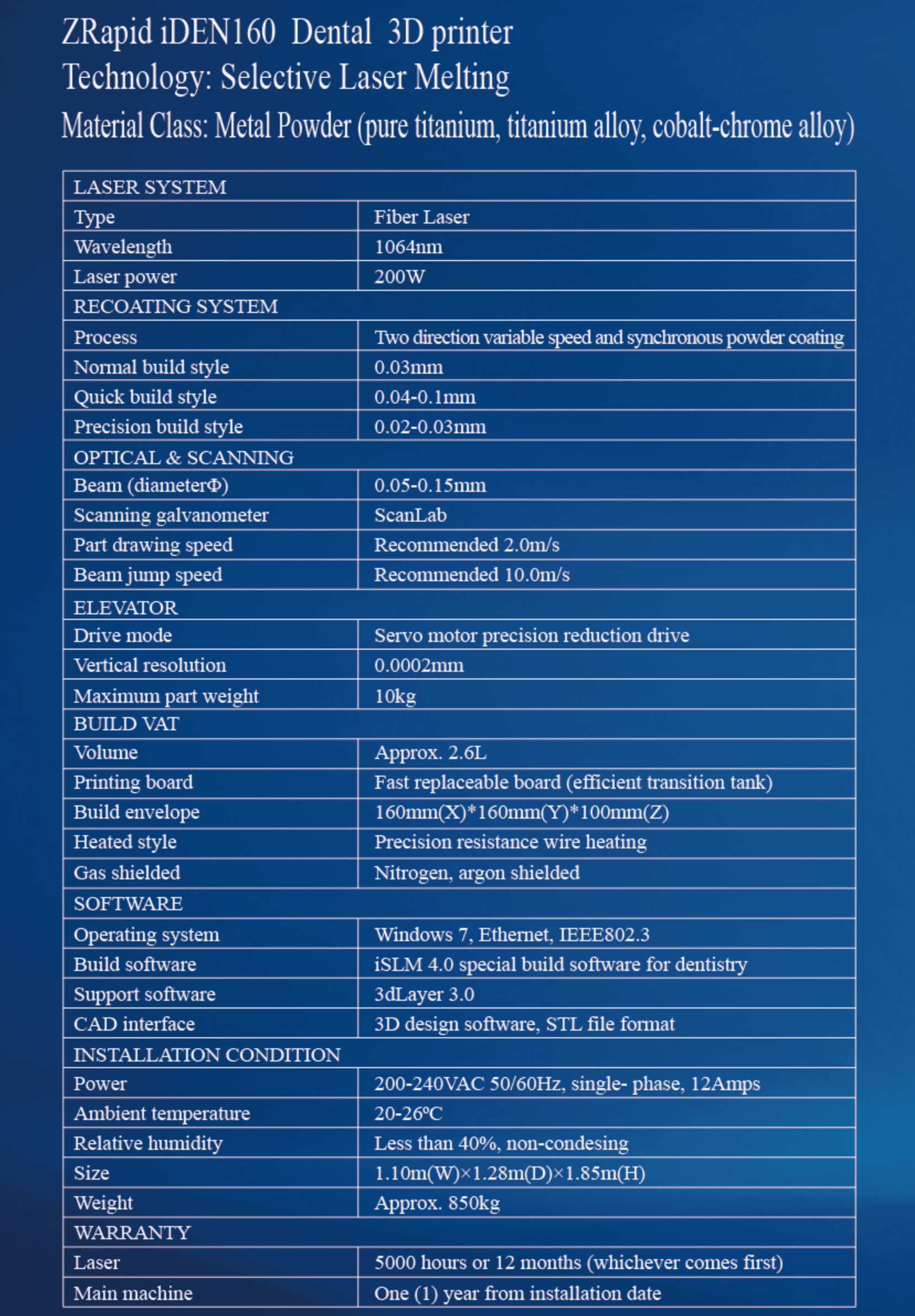

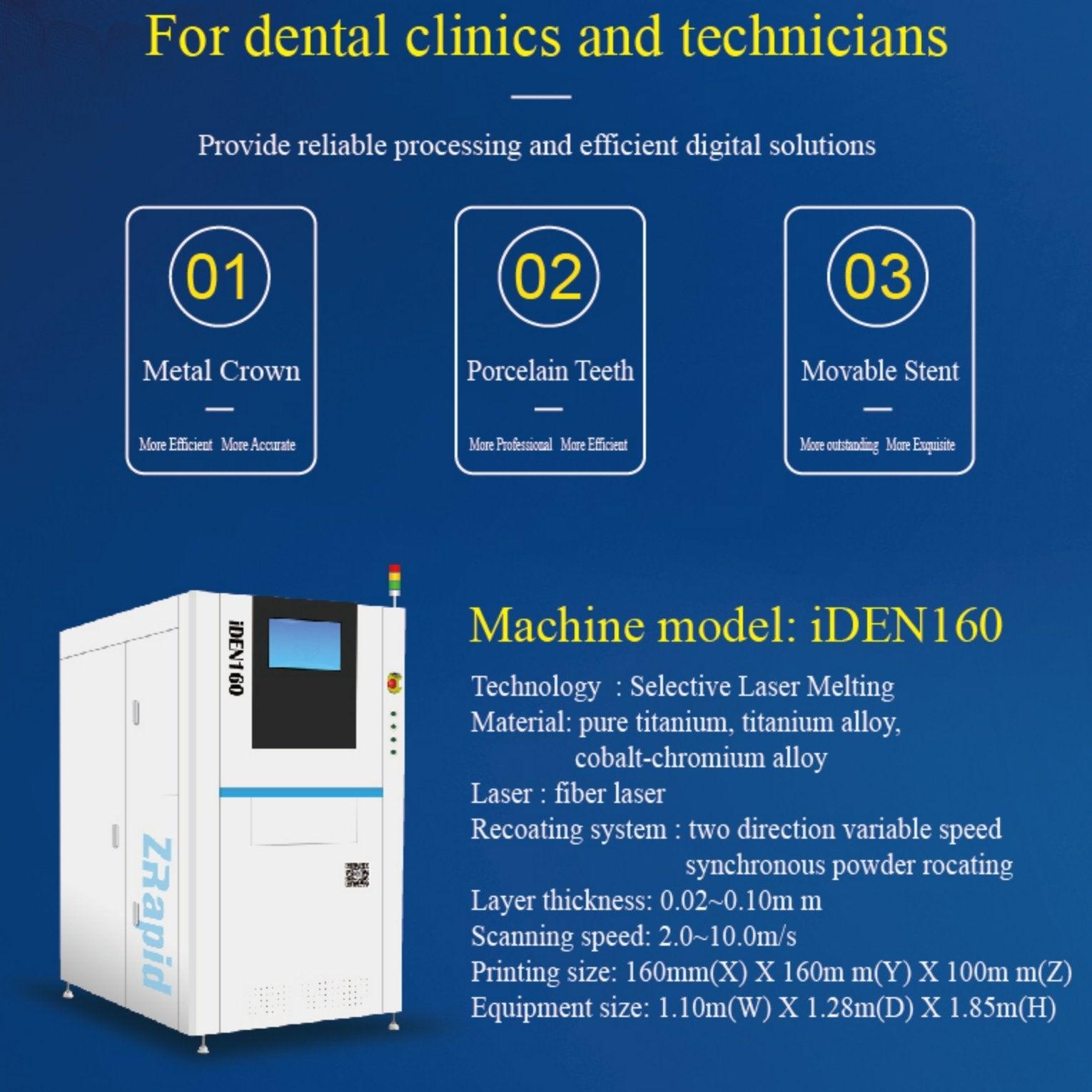

Zrapid iDEN160 metal 3d printer for dental industry 160*160*100mm

ZRapid Tech is a national high-tech enterprise dedicating to Industrial 3D Printing equipment, 3D Printing software, 3D Printing materials development, production, sales and technical services. We are the leading supplier of 3D printers in China and we provide a one-stop 3D printing solution globally.

Zrapid iDEN160 advantage

- Compact structure & Powerful function: The design concept of denture processing chair side equipment, Simple and practical appearance, Including the mechanical body, laser and optical scanning system, re-coating and feeding power system, dust removal and purification system software control system, etc. The machine is only 1.10m(W)X 1.28m(D)X 1.85m(H), Very suitable forworking in small places.

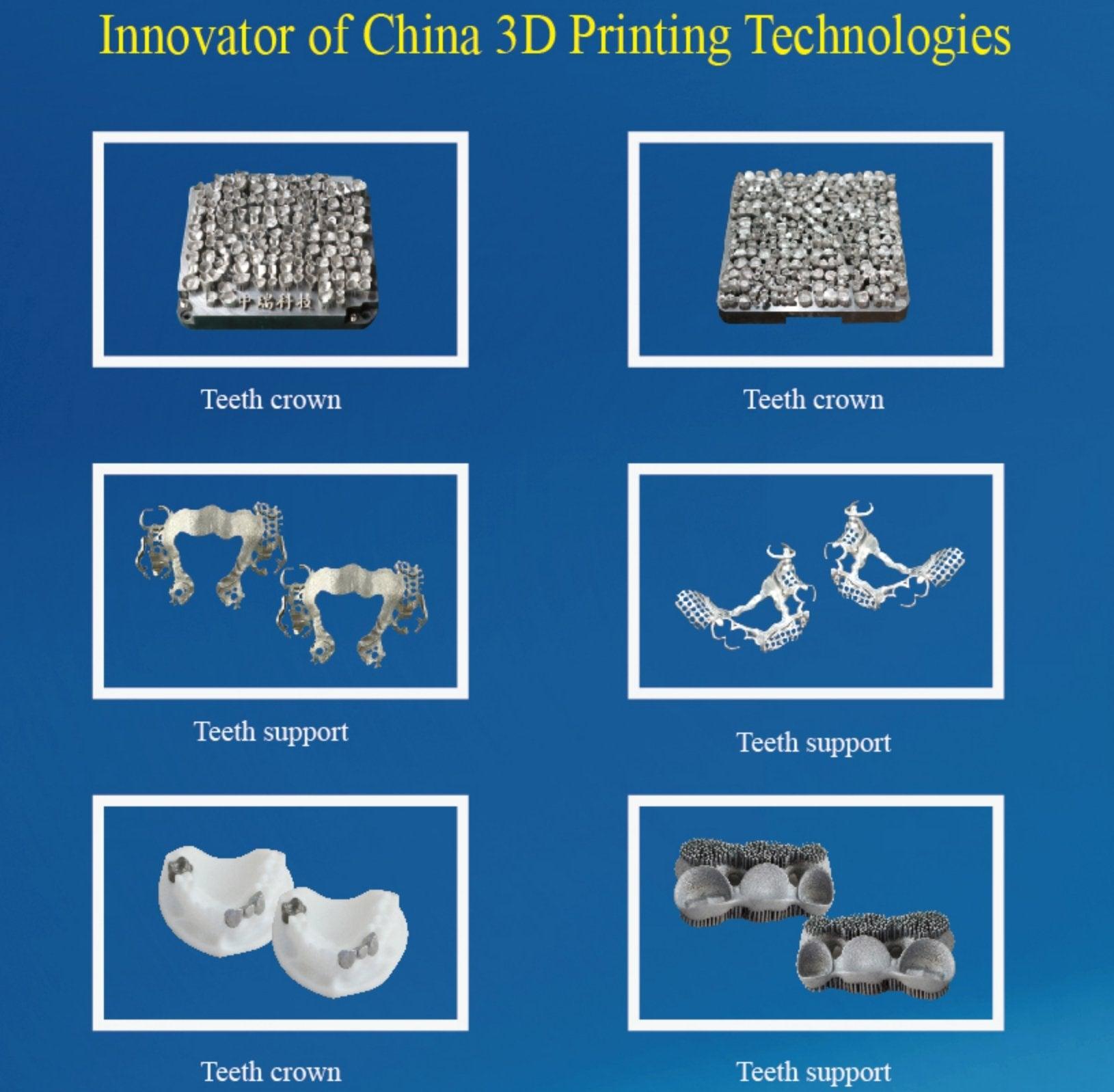

- Efficient batch production precision assurance: The equipment fully considers mass production . The maximum daily production capacity is 1200 crowns or 60 Oral Support , highest in the market now .

- Four stage dedusting purification: Four-stage dust removal and purification function to ensure a clean cycle of inert gas . The replaceable secondary filter can be filled with water or oil , and the filter element can be replaced safely . Suitable for processing pure titanium , titanium alloy and other active metal powders . The filter element with automatic powder cleaning function can be used for a longer time

- Two direction variable speed, synchronous powder coating: The motion control adopts a professional controller , which coordinates the orderly operation of various moving parts . The use of two-way variable speed synchronous powder re-coating system not only ensures the smooth re-coating of powder , but also increases the processing speed

- Efficient transition tank: The mass production equipment does not need to open the building chamber door after printing , Can transfer the substrate plate and materials by the transition chamber , thereby greatly reducing the overflow of inert gas , reducing the oxygen exhaust time during continuous printing , saving time and gas cost .

- Optimized solid support: The self-developed columnar solid support and Easy-to-use typesetting software: which is reasonable and accurate , and it is developed for dental 3D printing . Thecolumnar solid support can greatly reduce the deformation of the movable stent , andeasy to remove the support

- Fast replaceable board: The substrate plate installation adopts a patented structure , which can be quickly replaced without adjusting the level . No screw holes on the substrate plates and no installation location is required . which increases the use area of the substrate so that more samples

- Video monitoring: analysis ( optional )Video detection can capture and save the visual images before and after powder coating , and monitor printing quality through image analysis o Provide a visual analysis report of each layer after printing

Zrapid iDEN160 ACCESSORIES:

| No. | Description | Quantity |

| 1 | Water chiller for laser | 1 set |

| 2 | Sand blasting machine | 1 set |

| 3 | Vacuum oven | 1 set |

| 4 | Metal powder sieve | 1 set |

| 5 | Mechanical toolbox | 1 set |

| 6 | 200mm vernier caliper | 1 set |

| 7 | Cleaning tools including blade, plastic box, brush and the material cup. | 1 set |

| 8 | Software including device driver, control software ZERO and preparation software 3dLayer, etc. | 1 set |