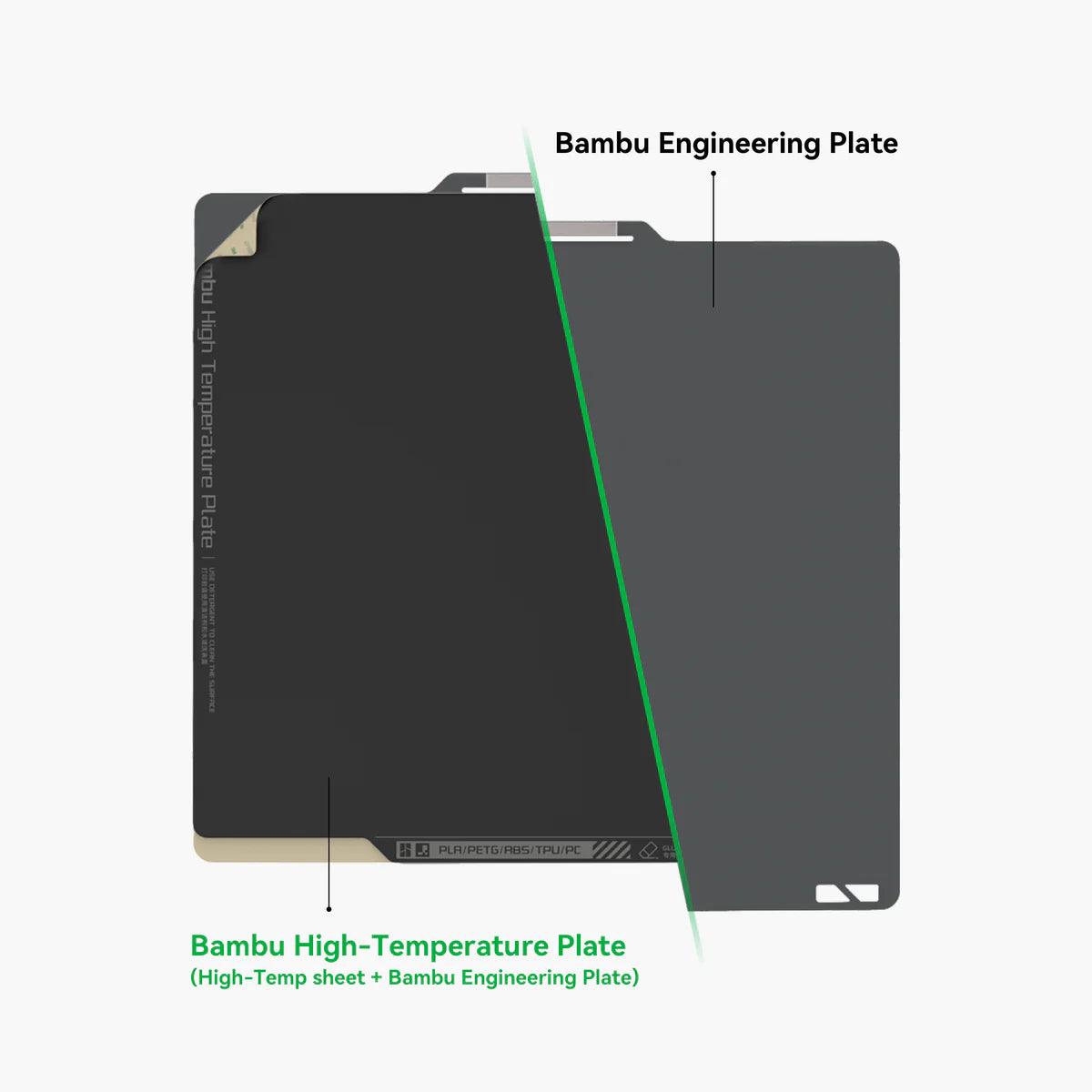

Description

One side: Bambu High-Temperature Plate = High-Temp sheet + Bambu Engineering Plate

The other side: Bambu Engineering Plate

1.Bambu High-Temperature Plate

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

| Material | Heatbed Temperature | Glue Stick Required? | Upper Glass Cover Plate Removed? |

| PLA/PLA-CF/PLA-GF | 45~65℃ | No | Yes |

| PETG/PETG-CF | 60~80℃ | Yes | No |

| ABS | 90~100℃ | Recommended | No |

| ASA | 90~100℃ | Recommended | No |

| TPU | 35~45℃ | Recommended | Yes |

| PVA | 45~60℃ | Recommended | Yes |

| PC/PC-CF | 100~110℃ | Yes | No |

| PA/PA-CF/PAHT-CF | 100~110℃ | Yes | No |

| PET-CF | 80~100℃ | Yes | No |

Benefits

Works best with most 3D printing filaments

Works well with the Automatic Calibration for Flow rate and does not interfere with the LIDAR

Smooth texture on the surface of the print

Excellent adhesion and easy print removal

Can be replaced by the user

Downsides

It cannot be used without heating the printing surface

Can be more fragile compared to the Engineering Plate or Textured PEI Plate

The upper glass cover plate, or the front glass door need to be opened for filaments with a low glass transition temperature

2. Bambu Engineering Plate

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

| Material | Heatbed Temperature | Glue Stick Required? | Upper Glass Cover Plate Removed? |

| TPU | 30~35℃ | Recommended | No |

| PETG/PETF-CF | 70~80℃ | Recommended | Yes |

| PET-CF | 70~80℃ | Recommended | Yes |

| ABS | 100~110℃ | Yes | No |

| PC/PC-CF | 100~110℃ | Yes | No |

| PA/PA-CF/PATH-CF | 100~110℃ | Yes | No |

Product Specification

| Material |

Smooth PEI sheet + Spring steel + Engineering Coating

|

|

Surface temperature resistance

|

Up to 120℃ |

| Flexible spring steel thickness |

0.4 mm

|

|

High-temp Plate sticker thickness

|

0.03 mm

|

|

Usable print size

|

256*256 mm

|

|

Package size

|

290*290*4 mm

|

|

Package weight

|

450 g

|

|

Color

|

Black

|